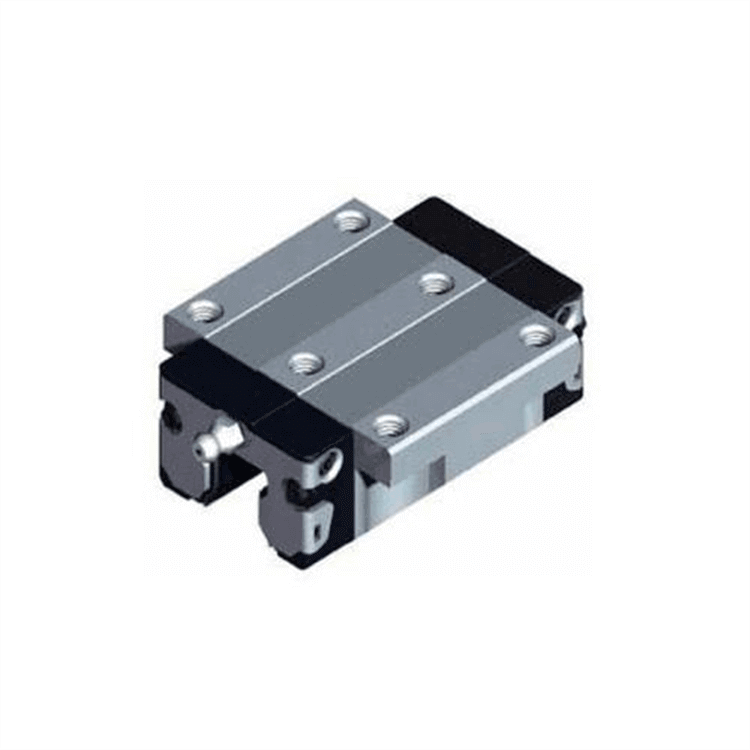

The ball guide block is a mold component which can slide in a certain Angle perpendicular to the direction of the opening and closing mode or in the direction of the opening and closing mode. When the product structure allows the mold to use the slider without the ball guide block, it is necessary to use the slider. The material itself has the proper hardness, wear resistance, enough to bear the friction of the movement. The cavity part or core part of the slider must be the same level as the other part of the mold core.

Industrial equipment

Mould is one of the important technology and equipment, production of various industrial products with the rapid development of plastic industry, as well as plastic products in aviation, aerospace, electronics, machinery, shipbuilding and automobile industries, products is becoming more and more high to the requirement of the mould, the traditional mould design method has been unable to adapt to today's requirements. Compared with the traditional mould design, computer aided engineering (CAE) technology both in terms of improve productivity, ensure the quality of products, or in terms of reduce cost, reduce labor intensity, has great superiority.

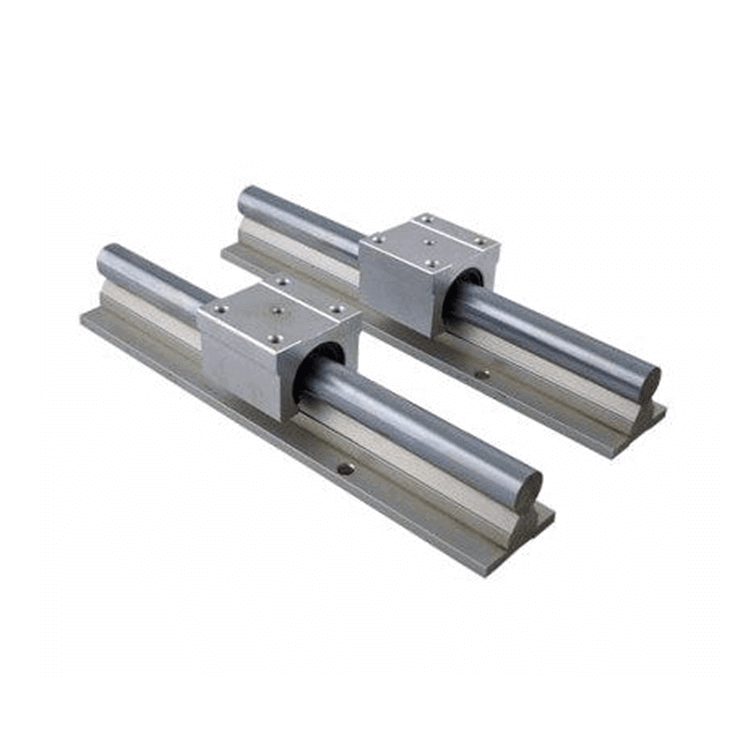

Linear ball guide

It mainly consists of ball guide block and guide rail, which is mainly used for sliding friction guide. Linear guide is also called line rail, slide rail, linear guide, linear slide rail, used for straight line reciprocating movement situation, and can bear certain torque, can be achieved under the condition of the high load and high precision linear motion. In China, linear guide rail, Taiwan is generally known as linear guide rail, linear slide rail.

The linear guide movement is used to support and guide the moving parts, and to reciprocate in a given direction. According to the nature of friction, linear motion guide can be divided into sliding friction guide, rolling friction guide, elastic friction guide, fluid friction guide and so on. Linear bearings are mainly used in automatic machinery, such as German imported machine tools, bending machine, laser welding machine, etc., of course, linear bearings and straight spools are used for matching. Like linear guide rail is mainly used in the high precision of the mechanical structure, straight line.

ball guide linear

The moving element of the guide rail and the fixed element do not use intermediate medium, but use rolling steel ball.

slider-crank

An overview of the ball guide block

Slider-crank mechanism as a kind of common institutions, in the machinery is mainly used for converting continuous rotation reciprocating movement or convert reciprocating movement to continuous rotation, the automatic feeding mechanism, punch and internal combustion engines are widely used in machinery, etc.

The original work of ball guide block

A planar connecting rod mechanism with crank and slider to achieve rotation and movement of each other is also known as crank connecting rod mechanism. The components in the slider mechanism of the crank slider are the sliding block, and the member of the crank and the slider is connected by rotating the sub-a and B.

When the mechanism is moving, the trajectory of the hinge center B does not pass through the crank's rotational center OA, which is called the offset crank slider mechanism, where e is the offset. If the different components are the frame, then the rotating guide bar mechanism, the crank block mechanism and the mobile guide rod mechanism can be obtained. If the guide bar and sliding block in the crank mechanism are changed, the swing guide bar mechanism is obtained. If the track mm of sliding block B is through OA, it is referred to as the heart crank slider mechanism.

The crank slider mechanism is widely used in the main body of reciprocating piston type engine, compressor, punch, etc., and the reciprocating movement is converted into a rotary motion that is not whole week or whole week. The compressor, punch and crank are the active parts, turning the whole turning movement into reciprocating movement. The sliding block of the offset crank slider has a quick return characteristic. The sawing machine is used to achieve the purpose of the slow and short return of the saw blade.

When OA=AB, when OA=AB, the motion trajectory of D point (AD=AB) is straight out, and the other points on the connecting rod are moving along the ellipse, which is also known as the elliptical instrument.

The motion characteristic of crank slider is usually expressed by the relation curve of crank Angle and sliding block stroke s. If it is a crank slider mechanism, there is no quick return characteristic, the pole position is zero.

Maximum velocity position of ball guide block

According to the ratio between the maximum speed and the average speed of the working stroke of the slider, a crank slider mechanism is designed. The first problem is to determine the maximum velocity position of the working stroke of the slider. For different types of slider-crank mechanism in slider article discusses the position of the maximum velocity concluded that offset slider-crank mechanism, the slider maximum speed in the crank and connecting rod perpendicular; Head-on slider-crank mechanism, the slider maximum speed is generally not in the crank and connecting rod perpendicular, along with the increase of the length slider at the maximum speed of crank and connecting rod approximates to 90 °.

When the slider-crank mechanism with other agencies, such as gear and rack mechanism, CAM mechanism in series into a composite structure, to achieve a specific function, often based on the maximum speed of slider work schedule and work schedule average velocity ratio of the delta m = C Max nu/nu C for design parameters, such as, therefore understand the slider working stroke the maximum speed of position on the organization's design is of prime importance.

Through the calculation of slider-crank mechanism model and the movement of the slider, using Excel equation of computing, avoids the complex function and the difficulty of extremum and Excel method is simple, fast operation, high calculation precision, fully meet the requirements of engineering design. Understand the different types of slider-crank mechanism in the slider position of maximum speed problems, help the designer understand slider-crank mechanism and characteristics of movement according to the requirement of the engineering practice of design parameters, such as gamma, lambda values, make a design personnel little detours, improve the efficiency of design, the design of connecting rod mechanism has important guiding significance.

Application of editing of ball guide block

Widely used in the spraying equipment, numerical control machine tools, machining center, electronics, automation machinery, textile machinery, automobile, medical equipment, printing machinery, packaging machinery, woodworking machinery, mold cavity, and many other fields.

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.