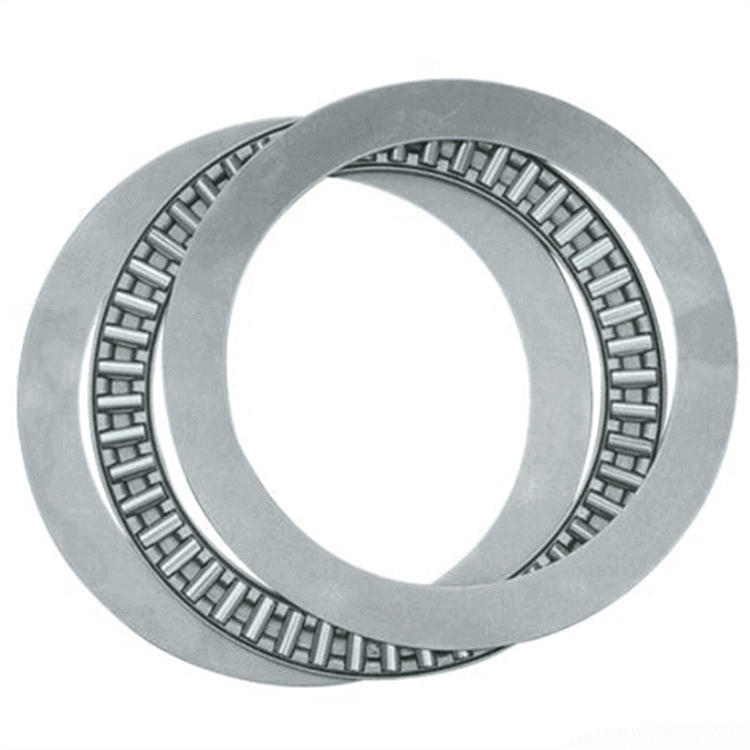

Thrust AXK needle roller is an important part of modern machines, plays a role in rotation, and can reduce the coefficient of friction, thrust needle roller is a kind of rolling bearing, composed of a thrust cage assembly with needle roller or ball and thrust washer, needle roller and cylindrical roller guided and organized by the thrust cage, when used with different series of axk bearing rings, it can be used to improve many different combinations for the bearing configuration, due to the selection of high-precision needle rollers to increase the contact length, This allows the bearing to achieve high load capacity and stiffness in a small space.

If the surface of adjacent parts is suitable for raceway surfaces, washers can be omitted, making the design more compact and reducing some edge pressure. The thrust needle roller is equipped with a shaped cage, which can fix and guide a large number of needle rollers in a reliable environment, and in the same assembly, because the diameter deviation is small, the bearing can bear heavy axial loads, prevent the external force generated at both ends of the needle roller, and thus play a role in extending the service life. Important elements of the thrust axk bearing needle roller and cage assembly are cold drawn from sheet steel, while smaller ones are made of plastic to ensure even load distribution.

The main causes of damage to axk bearing needle rollers are:

(1) Material fatigue; (2) poor lubrication; (3) pollution; (4) Installation problems; (5) Improper handling.

In general, damage to needle roller bearings is caused by material fatigue; One-third is caused by material fatigue. A third is due to poor lubrication; The other is due to the entry of contaminants into the needle roller bearings and the beginning of damage: the length of time from the needle roller bearing to the appearance of material fatigue points is related to the number of revolutions, load size, lubrication and cleanliness. This is the result of periodic shear stress under the loading surface. After a while, small cracks will be raised, which will gradually expand to the surface. When the rolling elements pass through small areas formed by these cracks, some cracks begin to fall off, forming the so-called peeling phenomenon. As the spalling continues to expand, needle roller bearings will be damaged and unusable. Initially occurs below the surface. Although the initial peel is usually small, the peel area will expand as stress increases and cracks increase. The process usually lasts a long time and generates noticeable vibration and noise. Therefore, there should be enough time to replace it and then damage axk bearing.

Welcome to contact me to get the price of axk bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.