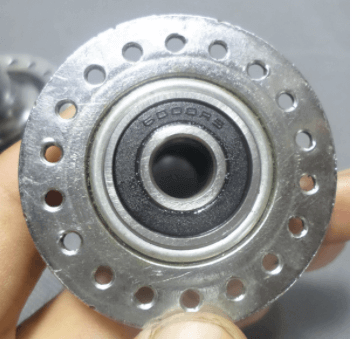

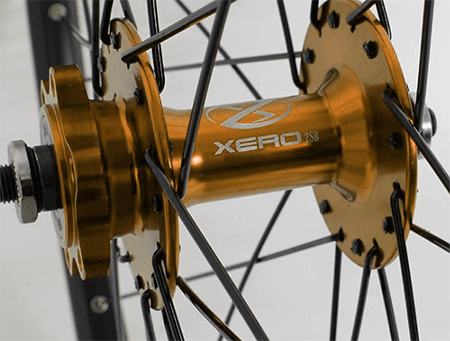

The front and rear wheel ball bearing for cycle are both outer ring rotating, which is equivalent to double row angular contact ball bearings.

The rear wheel ball bearing for cycle mainly bears rotating load; the front wheel ball bearing for cycle mainly bears fixed load.

The bicycle is driven by a chain. The pedal drives the front sprocket and transmits it to the rear sprocket. The chain gives the rear wheel a torque to drive the rear wheel to rotate. The rear wheel and the outer ring of the bearing are fixed together, the steel ball rotates and revolves, and the inner ring is stationary.

The forward force gives a torque to the front wheel, and the outer ring of the front wheel ball bearing for cycle rotates together with the front wheel. The steel ball rotates and revolves to move forward.

When cornering, the front wheel ball bearing for cycle bears the tilting torque on one side.

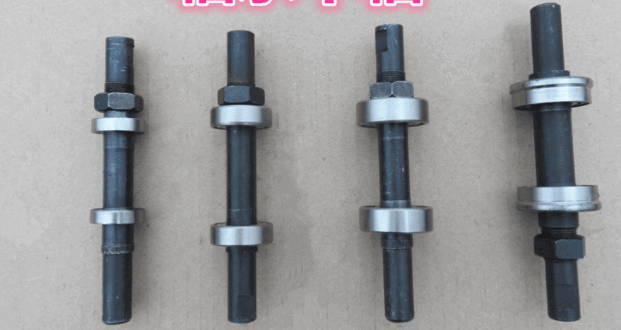

Because a safety clutch (consisting of star wheels, balls, springs, etc.) is installed on the ball bearing for cycle, when pedaling forward, there is a spring against the balls to make the bearing and gear chain run synchronously. When backward, the spring When squeezed to shorten, the ball moves backward, so the chain gear rotates backward, but the bearing (wheel) does not rotate

Reasons why bicycle wheels use balls instead of bearings:

1. The loose ball (ball) structure is easy to repair, and the wheel set using industrial bearings needs special tools to be disassembled when replacing the bearings.

2. The loose ball (ball) structure is actually a kind of bearing, called angular contact bearing, whose mechanical properties are more perfect than industrial bearings. It's just that the sealing performance is poor and it is easy to enter the dust and debris.

3. The steering performance of wheels with loose ball structure is better.

Welcome to contact me to get the price of ball bearing for cycle!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: (86)18363031398

Wechat:18363031368

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.