Installation and removal of ball bearing rod end

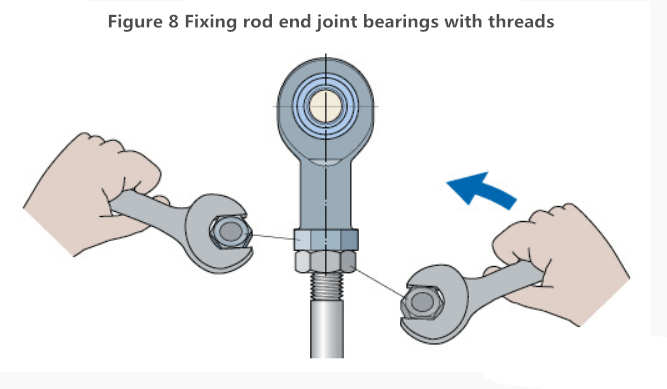

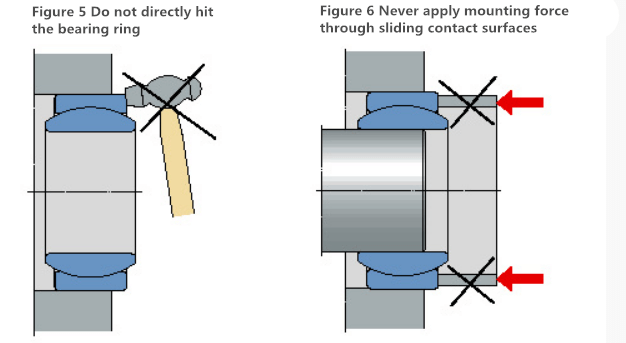

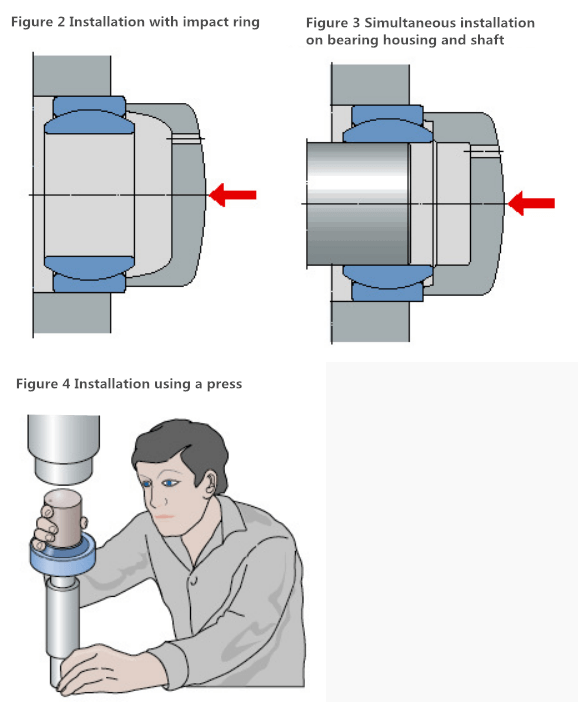

1. Where the press is lacking or cannot be used, the ball bearing rod end can be installed with an assembly sleeve and a small hammer. The hammering force should be evenly transmitted to the entire circumference of the end surface of the ball bearing rod end ferrule, so the end surface of the assembly sleeve that is hammered should be made into a spherical shape.

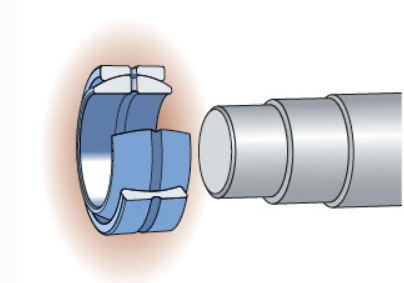

2. The force required to install the ball bearing rod end is related to the size of the joint bearing and the size of the matching interference. For medium or large joint bearings with large interference, the hot-fitting method is commonly used. Put the ball bearing rod end or the separable joint bearing ring into the oil tank or special heater and heat it evenly to 80-100°C, not more than 100°C before hot-assembly.

3, hot loading ball bearing rod end requires skilled operation skills. After the joint bearing is taken out of the heating oil tank or heater, immediately wipe off the oil and attachments on the joint bearing surface with a clean cloth (note that cotton yarn cannot be used), and then place it in front of the mating surface. The joint bearing is pushed to the position against the shaft shoulder. Always push tight during the cooling process, or use a small hammer to tap the joint bearing through the assembly sleeve to make it tight. Rotate the joint bearing slightly when installing the ball bearing rod end to avoid tipping or jamming during installation.

4. When the outer ring of the ball bearing rod end is tightly fitted with the housing hole, the housing can also be heated and installed into the joint bearing. In particular, the joint bearing of light metal materials may damage the mating surface due to the pressing of the outer ring during the tight fitting process. In this case, the ball bearing rod end should be heated first.

Repair ball bearing rod end

The usual ball bearing rod end repair varieties are as follows

Regular maintenance: In order to ensure the normal operation of the main engine, according to the request of the main engine and the design theory and application experience of the bearing, a maintenance cycle is set for regular maintenance.

Fault maintenance: When the bearing is faulty, stop for inspection and maintenance.

Early-warning maintenance: applying advanced bearing fault diagnosis technology, real-time monitoring of the operating state of the bearing, warnings before the bearing fault occurs, and stopping maintenance.

During the operation of the bearing, there must be sound, temperature and vibration phenomena. Therefore, with regard to the maintenance of the bearing in operation, abnormal changes in the bearing can be found by listening, touching, observing, and using bearing fault diagnostic equipment, and judging whether the ball bearing rod end is in a normal working state according to the changed state.

Welcome to contact me to get the price of ball bearing rod end!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: (86)18363031398

Wechat:18363031368

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.