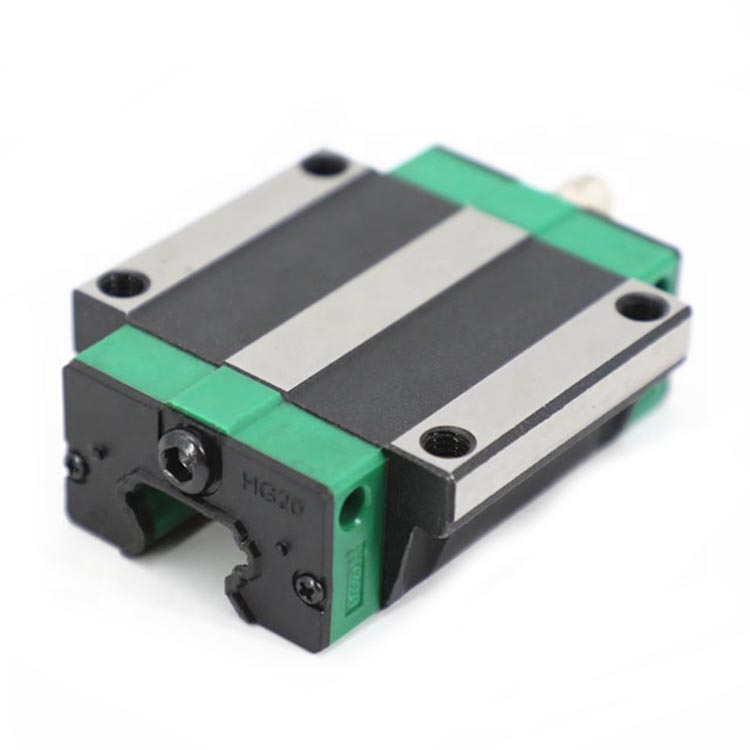

Application field of ball bearing slide rails

1, ball bearing slide rails are mainly used in automated machinery, such as imported German machine tools, bending machines, laser welding machines, etc., of course, ball bearing slide rails and linear axes are used.

2, ball bearing slide rails is mainly used in the mechanical structure with higher precision requirements, the moving material between the linear guide rail and the fixed component does not use the intermediate medium, but the rolling steel ball. Because the rolling steel ball is suitable for high-speed movement, small friction coefficient and high sensitivity, it can meet the working requirements of moving parts, such as tool holders and carriages of machine tools. If the force acting on the steel ball is too large, the steel ball is subjected to the preloading time for too long, resulting in an increase in the kinematic resistance of the bracket.

With ball bearing slide rails, we should note:

Ball bearing slide rails are precision parts, so they require a very careful attitude when used. Even if high-performance linear guides are used, if they are not used properly, the expected performance will not be achieved and the ball bearing slide rails will be damaged easily. Therefore, the following matters should be noted when using linear guides:

Prevent rust ball bearing slide rails

When taking the ball bearing slide rails directly, remove the sweat from your hands and apply high-quality mineral oil before handling. Pay special attention to rust prevention during the rainy season and summer.

Keep the ball bearing slide rails clean

Keeping the ball bearing slide rails and their surroundings clean, even if tiny dust that is invisible to the naked eye enters the rails, it increases the wear, vibration and noise of the rails.

Be careful when installing ball bearing slide rails

Linear guides should be carefully and carefully used during installation. Strong stamping is not allowed. It is not allowed to directly hit the guide rails with a hammer. It is not allowed to transmit pressure through the rolling elements.

Ball bearing slide rails installation tools should be suitable

Ball bearing slide rails use special tools with the right and accurate installation tools, and try to avoid the use of cloth and short fibers.

ZYSL company specializes in ball bearing slide rails for many years. All raw materials and accessories have been carefully selected to ensure a good user experience.

Welcome to contact me to know the price of ball bearing slide rails!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.