The design concept of bearing end cap:

Bearing end cap, as one of the most important mechanical parts, is widely used. The main working surface of the part is the outer surface of the left and right end faces and the left end face.

(1) The axial positioning of the outer ring of the bearing;

(2) Dustproof and sealed, in addition to being dustproof and sealed, they often cooperate with seals to express the effect of sealing;

(3) The end cover located between the lathe motor and the spindle box mainly serves to transmit torque and buffer shock absorption, so that the rotation of the spindle box is stable

Second, the role of bearing end cap:

The majority of small and medium-sized reducers use rolling bearings, and the bearing end cap of the rolling bearing is the most common part. The bearing end cover is used to fix the bearing, adjust the bearing gap and withstand the axial force.

3. Structural characteristics of bearing end cap:

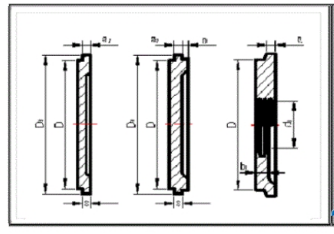

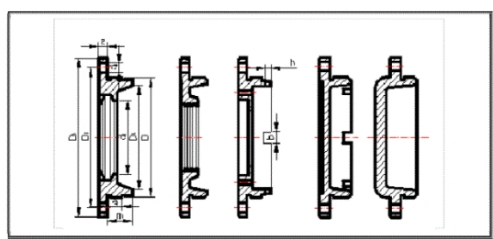

The structure of the bearing end cap has two types: embedded and flanged, each of which has a bulky cover and a through cover.

1. The embedded bearing end cap has a simple and compact structure without the need for fixing screws. The outer diameter is small, the weight is light, and the size of the outer secondary shaft is short. However, it is difficult to install and remove the end cover and adjust the bearing clearance, and the sealing performance is poor. Slotting on the seat hole requires time-consuming processing. The embedded bearing end cap is mostly used in the occasions with light weight and compact structure, and its structure and dimensions are shown in Table 1.

2. The flange bearing end cap is easy to install, remove and adjust the bearing clearance, and the sealing performance is also good. So it is widely used. But the disadvantage is that the outer size is large, and a set of screws is needed to connect. The structure and dimensions are shown in Table 2.

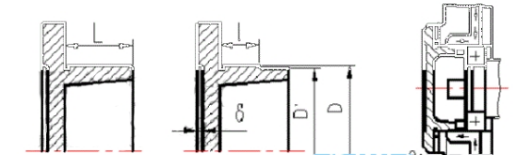

Note: When the mating part of the bearing end cap and the hole is long, in order to reduce the contact surface, a small diameter is cast or cast out in the Ruibu, but it must have sufficient length e1. Generally, the fitting length here is e1=( 0.10-0.15) D, where D is the outer diameter of the bearing, and the end face in the figure is recessed. The δ value is also to reduce the processing surface. As shown in Figure 3.

Welcome to contact me to get the price of bearing end cap!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.