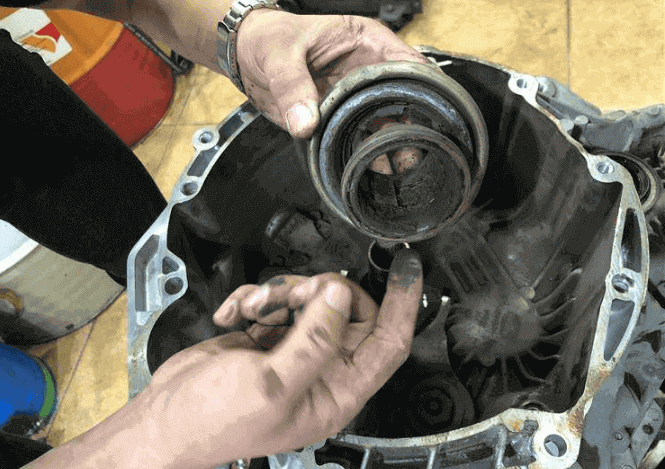

The most direct manifestation of bearing for gearbox damage is high noise and high temperature.

If the bearing for gearbox is seriously damaged, the shaft will be displaced and affect the transmission.

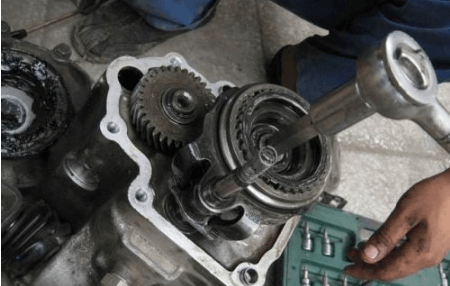

The gearbox mainly refers to the gearbox of the car.It is divided into two types: manual and automatic. The manual transmission is mainly composed of gears and shafts, and the variable speed torque is generated by different gear combinations; and the automatic transmission AT is composed of a hydraulic torque converter, planetary gears and a hydraulic control system. Variable speed torque can be achieved through the combination of hydraulic transmission and gear.

The function is:

1. Change the transmission ratio;

2. When the engine rotation direction is unchanged, the car can be driven in reverse; 3. Use neutral to interrupt the power transmission, so that the engine can be started, idle, and the transmission can be shifted or power output can be facilitated.

Gearbox requirements for bearings:

1. Consider the shape and connection dimensions of bearing for gearbox.

2. Bearing for gearbox can be placed horizontally or vertically or at an angle. Can rotate forward and reverse. Both positive and negative input and output power (i.e. deceleration or speed increase)

3. Regardless of the installation method used for bearing for gearbox, there are size matching requirements for its coupling.

Recommended use: H7/h6 for the fit of the inner ring hole d and the shaft; H7/r6 for the fit of the pin hole do in the middle ring and the drive; H8/h7 for the fit of the outer ring D and the housing; holes for the drive and output shaft The use of clearance fit, the clearance is 0.2~0.5mm.

4. Axial positioning of bearing for gearbox: After any one of the three turns is axially positioned, the other two axes do not need to be axially positioned.

5. The direction of rotation of the bearing for gearbox; the outer ring and the inner ring are positioned with flat keys. The middle ring is positioned using transmission.

6. Bearing for gearbox can bear smaller external force in radial direction, but should not bear larger working load.

7. The transmission ratio is based on the first installation method. If other installation methods are used, the transmission ratio should be calculated.

8. Under the rated speed (1500rpm), select the variable speed drive bearing model according to the transmission ratio and the required power (Kw).

9. When working torque is the basis, the bearing for gearbox model should be selected accordingly.

10. The selection of reducer model is consistent with the model of bearing for gearbox

Welcome to contact me to get the price of bearing for gearbox!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.