With the development of the bearing industry, steel bearings and full ceramic bearings can no longer meet the needs of many users. Steel bearings are cheap, but they have almost no corrosion resistance; full ceramic bearings have good corrosion resistance but are not impact resistant. It is also more expensive.

Under such circumstances, bearing hybrid ceramic was born. It not only has a certain corrosion resistance effect, the most important thing is that it has the self-lubricating effect of ordinary bearings, and the price is much lower than that of full ceramic bearings. Then let me introduce the bearing hybrid ceramic in detail!

1. What is bearing hybrid ceramic?

The purpose of replacing metal materials such as steel with ceramic materials as rolling elements is to take advantage of the wear resistance, corrosion resistance, high temperature resistance, electrical insulation (except SiC), non-magnetic conductivity, High strength, high rigidity, low specific gravity and other properties.

The use of ceramic materials can make the bearing hybrid ceramic operate normally at higher speeds, harsher environments and low lubrication conditions, and can reduce wear, noise, vibration, and maintenance easier, so as to achieve longer bearing life, and Significantly improve its performance and reliability. Suitable for making ceramic materials for bearings.

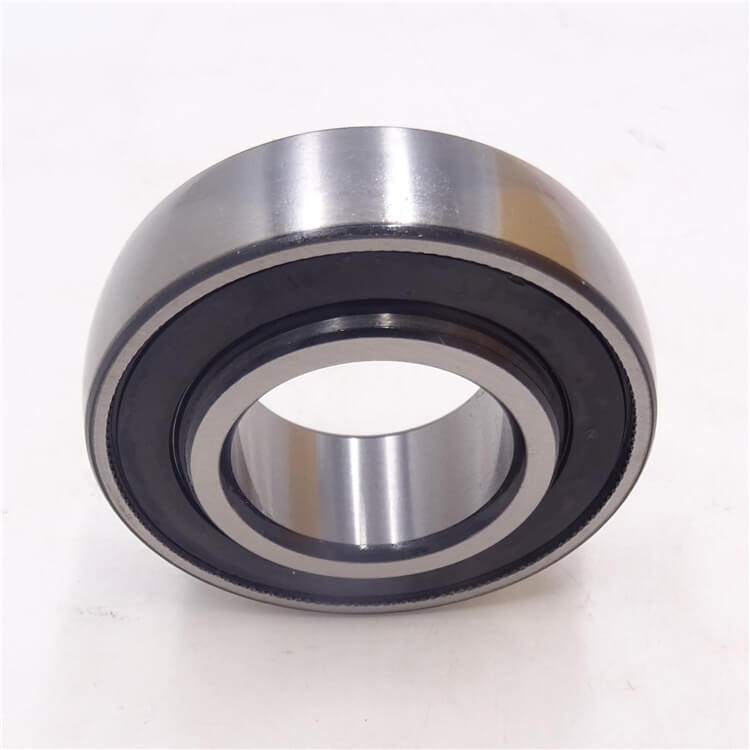

bearing hybrid ceramic structure: bearing steel ferrule, or stainless steel ferrule + ceramic ball + nylon retainer + rubber seal

2. Advantages of bearing hybrid ceramic

(1) bearing hybrid ceramic high temperature resistance

The thermal expansion coefficient of ceramic balls is small, and the bearing balls will not expand due to temperature in high temperature environments, which greatly increases the operating temperature of the entire bearing. The temperature of ordinary bearings is about 160 degrees, and the temperature of ceramic balls can reach more than 220 degrees.

(2) Bearing hybrid ceramic has a high rotation speed

Ceramic balls have oil-free and self-lubricating properties, and the friction coefficient of ceramic balls is small, so ceramic ball bearings have a high speed. According to statistics, bearings using ceramic balls are more than 1.5 times the speed of ordinary bearings.

(3) Long life of bearing hybrid ceramic

Ordinary bearings are used in water and high temperature environments, the grease is easy to wash off or dry out, so the bearing will soon be damaged. Using ceramic balls as rolling elements, this avoids the occurrence of premature bearing damage caused by the drying of grease in ordinary bearings; according to our test and some customer feedback, the service life of the bearing after using ceramic balls is 2- 3 times.

(4) bearing hybrid ceramic insulation

The rolling elements are made of ceramic balls, which can achieve insulation between the inner ring and the outer ring of the bearing. Because ceramic balls are insulators, using ceramic balls between the inner and outer rings of the bearing can achieve the effect of insulation. In this way, the bearing can be used in a conductive environment. This is also the biggest advantage of hybrid ceramic bearings.

(5) bearing hybrid ceramic oil-free and self-lubricating

Ceramic balls have oil-free and self-lubricating properties, that is to say, even if the grease dries out, the bearing can still operate, so ceramic ball bearings can be grease-free.

3. The purpose of bearing hybrid ceramic:

1. Car

For the bearings used in automobiles, the turbo charger bearings have the highest requirements for speed, which require the bearings to have good acceleration responsiveness, as well as low torque, low vibration and low temperature rise under high-speed rotation. Due to its low temperature rise during operation, it can reduce the amount of lubricating oil, so the oil stirring resistance is reduced, the bearing torque is reduced, and the speed is increased. In addition, bearing hybrid ceramics are also used in rail vehicles, whose durability and reliability under harsh conditions have been proven.

2. Motor

Electric motors can be used to achieve permanent insulation. When the motors are used for deceleration and energy-saving devices, internal leakage can cause arcing.

3. Aero Engine

In the fuel pump of an aero engine, it can work in liquid oxygen and liquid hydrogen for a long time. It has been proven that it will not be damaged after 50 launches.

4. Aircraft parts

The aircraft manufacturing industry has used ball screws with ceramic balls for aircraft flap adjusters, and has also tried to use bearing hybrid ceramics in gas turbine engines.

Welcome to contact me to get the price of bearing hybrid ceramic!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: (86)18363031398

Wechat:18363031368

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.