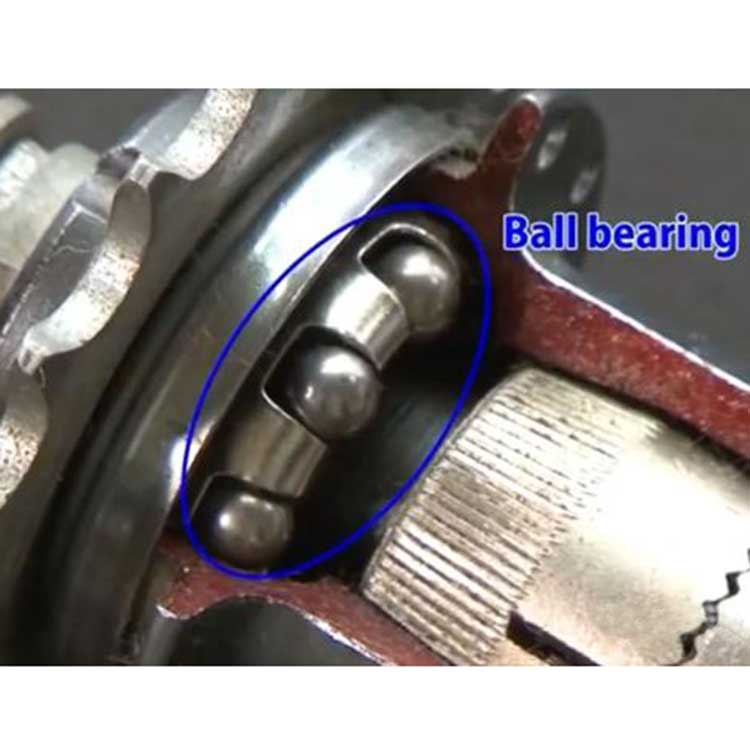

Today let's find out how the steel balls in the bearing made in japan are made:

Steel balls are indispensable for the bearing made in japan industry and crushing industry. Common steel balls include bearing made in japan steel balls, stainless steel balls, carbon steel balls, alloy balls, and so on. Although the steel ball is small, its load and life are very important in the world of transmission, and its production process directly affects product quality.

Let ’s take a look at the production process of advanced bearing made in japan steel balls:

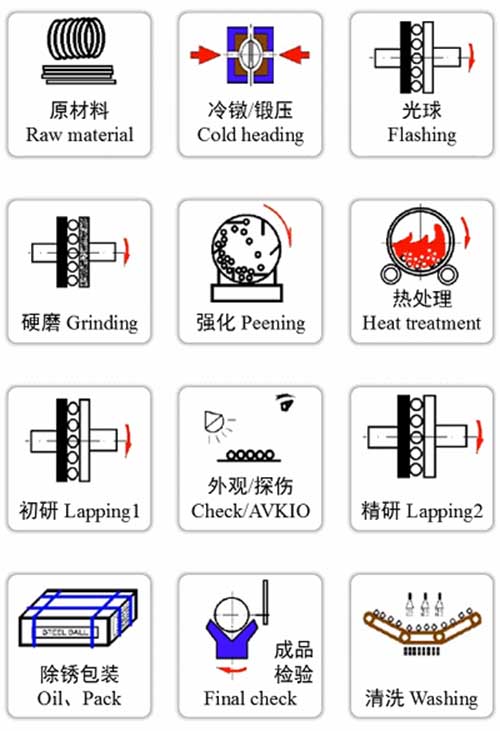

01 Raw material

The materials of each specification and each furnace number are inspected. If it is a wire, it also needs to be drawn (drawn), and the wire is drawn with a wire drawing machine to the required wire diameter.

02 Cold heading

Under normal temperature conditions, the raw materials are plastically deformed to form a ball.

03 Flashing

The endless belt on the surface of the ball is removed, and the roughness of the surface of the bearing made in japan steel ball is improved, so that the ball is initially spherical.

04 Heat treatment

The ball is put into a heat treatment furnace, carburized, quenched and then tempered to make the ball have a certain carburized layer and hardness, toughness and crushing load. Some manufacturers use advanced mesh belt heat treatment lines to effectively control the process parameters of quenching and tempering time and temperature through various instruments to ensure the stability and controllability of product quality.

05 Peening

A processing method in which steel balls collide with each other through a strengthening machine, so that the surface of the bearing made in japan steel balls is plastically strengthened to increase the compressive stress and surface hardness of the steel ball surface.

06 Grinding

By fixing the iron plate and rotating the grinding wheel plate under a certain pressure, the surface quality and shape of the bearing made in japan steel ball are further improved.

07 Lapping 1

Using two cast iron preliminary research discs, and then adding abrasives, through a certain pressure and mechanical movement, to achieve the surface quality specified by the process.

08 Check

100% manual selection. In addition, flaw detectors: three methods of photoelectricity, eddy current, and vibration are used to select various types of defect balls, such as surface defects, shallow surface layer cracks, and internal material defects.

09 Laping 2

Using two cast iron lapping plates and adding abrasives, under the action of a little pressure and mechanical movement, some reserves are consumed to further improve the accuracy and surface quality of the steel balls.

10 Washing

The spiral cleaning machine and the lifting turnover box improve the cleaning quality and reduce the damage to the surface of the bearing made in japan steel ball, and continuously filter the cleaning liquid to ensure the cleanliness of the steel ball.

11 Final check

For each batch of bearing made in japan steel balls, final inspection is performed according to the requirements of the process, such as the roundness, hardness, metallography, and stress of the steel balls.

12 Oil, Pack

Use anti-rust oil, spray anti-rust and pack according to customer's packaging requirements.

Welcome to contact me to get the price of bearing made in japan!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.