Clean

Motor bearings should generally be cleaned and refueled after 2000 hours of use. There are two methods for cleaning motor bearings:

I. Hot oil cleaning method

It is mainly used for best bearings for 3d printer hardened by soft dry oil or rust-proof paste. It should be immersed in hot engine oil at 100-200 ℃, clamp the best bearings for 3d printer with pliers, and clean the oil on the motor bearings with a brush. The soft dry oil or rust-proof paste melts when heated to 100-200 ° C, and is easily washed out from the gap of the motor bearing. Sometimes as long as the best bearings for 3d printer is shaken in the oil multiple times, the oil will also flow away from the gap.

When cleaning the motor's centripetal spherical best bearings for 3d printer, the ball, bead holder and inner ring should be turned out of the outer ring and then immersed in hot oil. The roller and ball should also be cleaned when the short cylindrical roller motor bearing is cleaned The frame, inner ring and outer ring are disengaged.

During hot oil cleaning, the temperature of the oil should not exceed 200 ° C. When heating directly with an open flame, care should be taken to prevent the oil from burning. The best bearings for 3d printer should be suspended in the oil pan, and the bottom will cause overheating and reduce the hardness.

Second, the general cleaning method

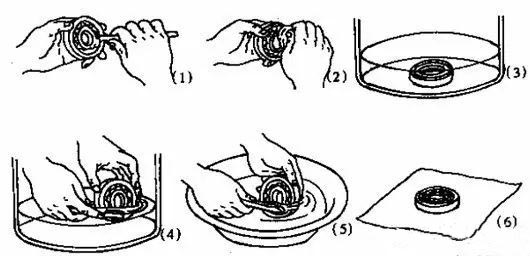

Immerse the best bearings for 3d printer in kerosene for 5-10 minutes, pinch the inner ring with one hand, and turn the outer ring with the other hand, and the dry oil or rust-proof paste on the motor bearing will fall off. Then put the motor bearing into a cleaner kerosene, brush it with a soft brush, clean the oil stains in the balls and the gap, wash it in gasoline again, and put it on clean paper after taking it out. When cleaning the radial spherical ball motor bearing and the short cylindrical roller motor bearing, the ball, bead frame, inner ring and outer ring should be separated and cleaned.

The best bearings for 3d printer mounted on the shaft are mainly cleaned by spraying oil or spraying with an oil gun. The oil that is easy to clean is kerosene first and then gasoline; the oil that is difficult to clean is first washed with hot engine oil at 100-200 ° C. Wash or spray with oil gun, and then wash with gasoline. Be careful not to use a sharp tool to scrape hard grease or rust on the motor bearings, so as not to damage the finish of the motor bearing rolling elements and the groove ring parts, and clean the motor bearings with a clean cloth.

Inspection and installation method

1. Before inspecting the best bearings for 3d printer, first take out the old lubricating oil from the inner and outer small caps of the bearing, and then clean the inner and outer small caps of the bearing with a gasoline brush. After cleaning, clean the bristles or cotton wires, and do not leave them in the bearing.

2. Carefully inspect the bearings after cleaning. The best bearings for 3d printer should be clean and intact, without overheating, cracks, peeling, groove impurities, etc., the internal and external raceways are smooth, and the clearances are acceptable. If the support frame is loose, it will cause friction between the support frame and the bearing sleeve. When this happens, new bearings should be replaced.

3. After maintenance, the best bearings for 3d printer should rotate flexibly without jamming.

4. Check that there is no wear on the inner and outer covers of the bearing. If there is any wear, the cause should be found and handled.

5. The fit between the inner sleeve of the best bearings for 3d printer and the shaft should be fastened, otherwise it should be handled.

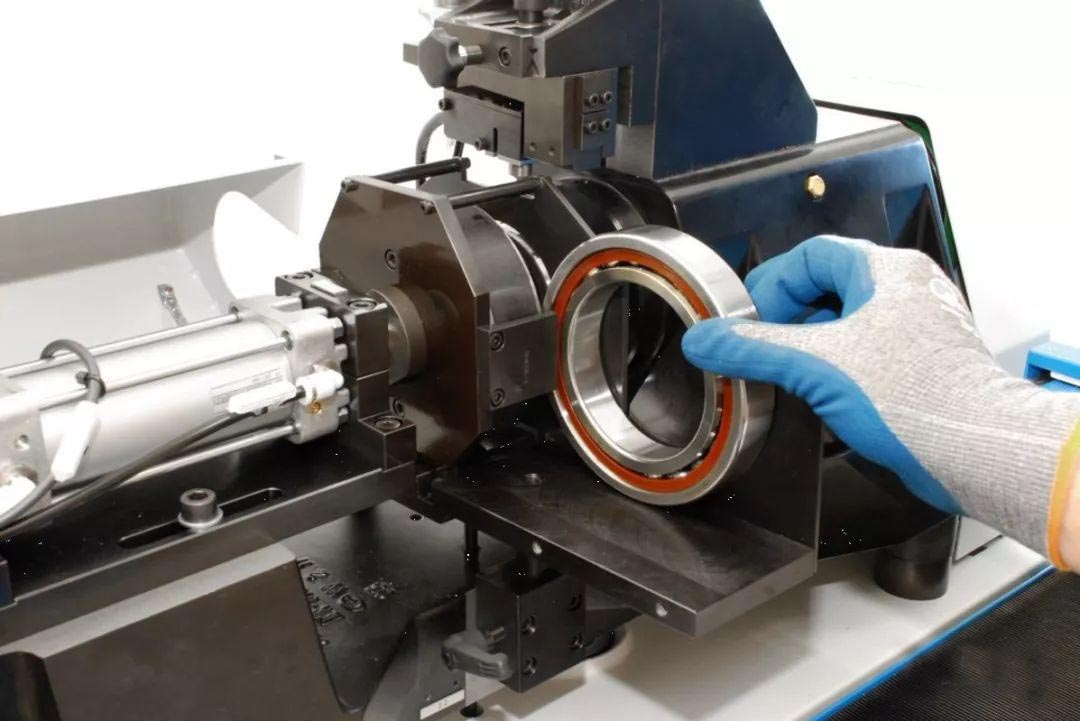

6. When assembling new best bearings for 3d printer, use oil heating or eddy current method to heat the bearings. The heating temperature is preferably 90 ~ 100 ℃. Set the bearings on the motor shaft at high temperature and ensure that the bearings are in place. Bearing up to avoid damage to the bearing.

Welcome to contact me to get the price of best bearings for 3d printer!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.