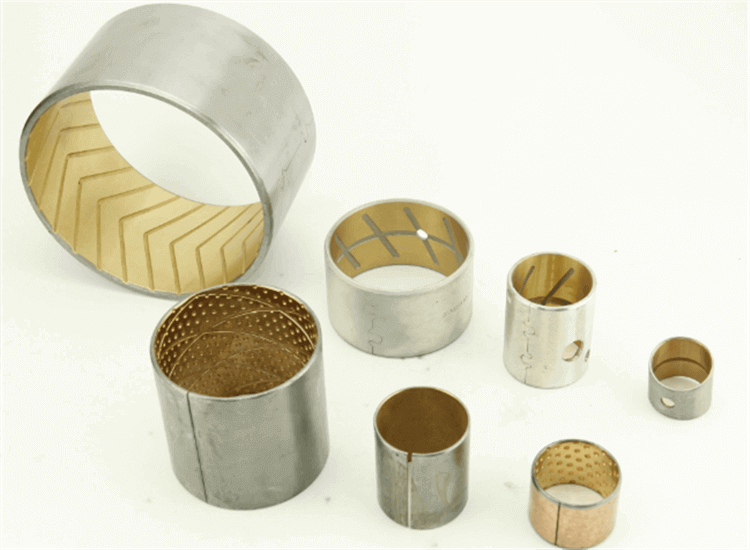

Bimetallic bearings

Bimetallic bearings are one of the oil-free lubricating bearings. The product is made of high-quality low-carbon steel backing. The surface is sintered with lead-tin bronze alloy. After several times of high-temperature sintering and compact rolling, the copper and steel integrated bimetal strips are formed. The material is rolled and is suitable for various types of applications such as bushes and thrust washers that are subjected to medium speed and high impact loads.

Bimetallic bearings steel material

Since the base body is stabilized as a low carbon steel material, the machining accuracy of the outer diameter of the sleeve is ensured, and no screw fixing is required after the product is installed in the seat hole, and the outer circle can be prevented by the interference fit. The chemical composition of the inner alloy layer can meet the different bearing pressures, different use temperatures and different sliding speed requirements. The friction surfaces can be designed in different ways to meet different fueling requirements and prevent biting. Axis phenomenon.

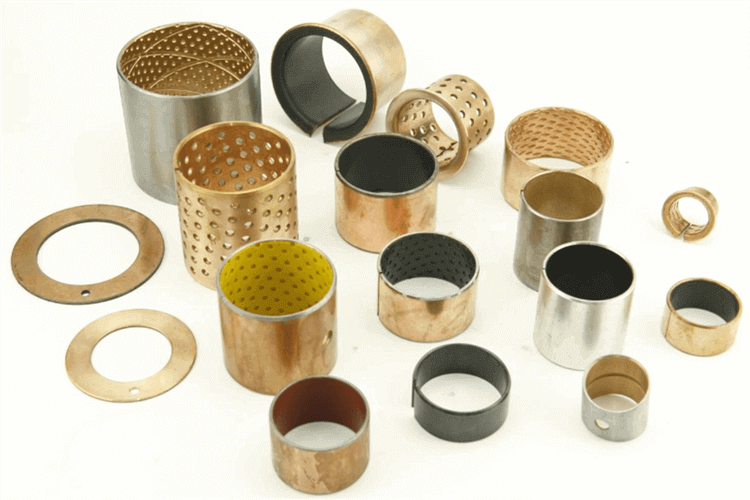

Bimetallic bearings

Bimetallic bearings have the advantages of good wear resistance. It is especially suitable for medium-speed medium-load and low-speed high-load applications. Through special process means, various oil grooves, oil holes and oil holes can be processed on the friction surface to adapt to the use under different lubrication conditions. Bimetallic bearings have been widely used in automotive engines, chassis, motorcycle clutches, gear pump wipers and lifting equipment.

Metal-based solid-state self-lubricating bimetallic bearings (JDB) is a novel lubricated bearing that combines the characteristics of metal bearings and the characteristics of self-lubricating bearings. The metal matrix is subjected to load and the specially formulated solid lubricating material acts as a lubricant. It has the characteristics of high bearing capacity, impact resistance, high temperature resistance and strong self-lubricating ability. It is especially suitable for heavy load, low speed, reciprocating or swinging, etc., which is difficult to lubricate and form oil film. It is also not afraid of water and other acid etching. And scouring.

If you need the bimetallic bearings or other bearings, please contact me any time!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.