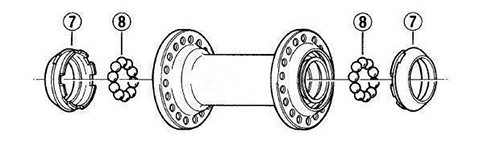

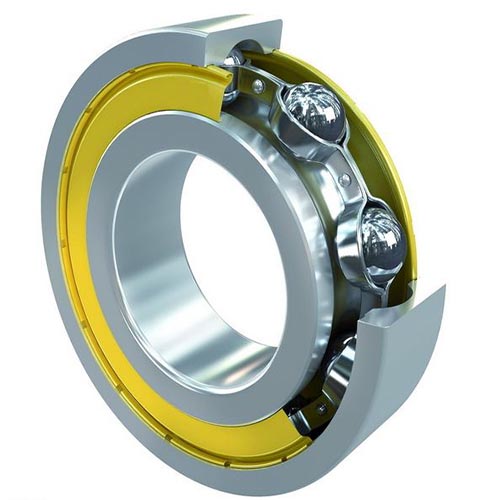

Generally, there are two main types of caged ball bearings bicycle: bearing and bead block. There is another weird thing about a rolling pin, so I won't discuss it here. This problem is mainly focused on the hub. Bearings in these places have requirements for lubricity and strength of axial force and radial force at the same time. In places like the rotation point of the shock absorber of the frame, the main consideration is the radial force, so almost all of them are bearing. Traditionally, the hub that is independently embedded in the bearing assembly is called "Peilin", and the two ends of the hub are driven into the pan bowl, the balls are discharged into the pan bowl, and the bearing driven by the rotation of the ball is called the "ball stop". In layman's terms, the bearing can be dismantled as a whole and become the ring-shaped "ball bearing" that everyone usually sees.

Begin to talk about the fundamental problem: the force on the caged ball bearings bicycle is divided into radial force and axial force. 1. When the bearing is subjected to radial force, there is little difference between the two, but in terms of axial force, because the bead stop structure has a bead bowl, it can theoretically withstand greater axial force and higher strength. 2. In terms of lubricity, the bearing is generally 7-8 beads, and the ball with cage is directly above and below the inner and outer slides, and the wrapping properties are closer to the hemispherical shape, making the rolling smoothness better. Since the ball gear structure does not have a cage, the ball can reach more than 9 balls. When the grinding accuracy is the same, the rolling resistance of this structure exceeds the 7-ball assembly type caged ball bearings bicycle. 3. Because the caged ball bearings bicycle has good sealing performance, it is not easy to enter water and sand, so the bearing can provide a better life without considering the high cost to solve the sealing performance. Among the above three points, the second and third points seem to be better for bearing bearings. But these two points are based on the consideration of cost.

In fact, in advanced wheels, in order to ensure caged ball bearings bicycle strength, lubricity and sealing, there is no compromise on cost. For example, for the hubs of XT and XT and above, the bead bowl, balls and gears are all processed by laser, and the accuracy is very high. This also results in the irreplaceability of these accessories: each hub is unique, and each accessory is adjusted according to the actual situation. So in summary, if the price is not considered, only strength, lubricity and sealing are considered comprehensively, the bead block structure has a perfect solution, but Peilin can only solve the lubricity and sealing. In view of the fact that the hub of the bead block structure needs to be considered in all aspects and the cost is very high, the common caged ball bearings bicycle are all bearings.

Welcome to contact me to get the price of double thrust bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.