Wear of car wheel bearings will affect the vehicle's braking efficiency, suspension and brake safety critical characteristics, especially in a high speed. Recommended every 12 to 24 months regularly check the wheel bearing. You can use the jack wheels lifted off the ground to complete this operationA. Hand wheel at the top and bottom of the wheel, wheel inward and outward swing. If the wheel lateral movement more than 1 cm, the need to replace the car wheel bearings.

Step 1: using the hand brake fixed vehicle. This will prevent the vehicle under the support of safety support moving forward or backward.

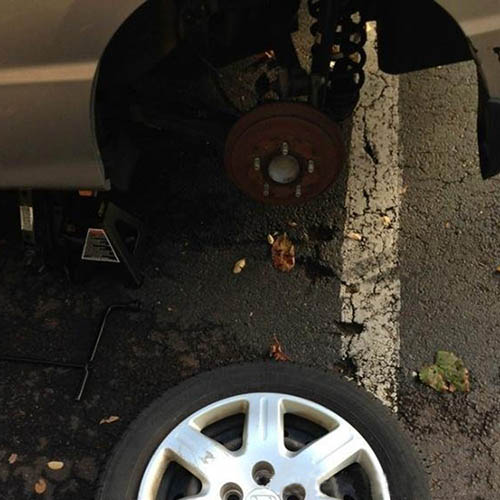

Step 2: loosen the front or rear wheel fixed nut, and the front or rear of the vehicle out of the ground. On the each side of the vehicle installation, sustained as below the vehicle safety. Remove the fixed nut and the front wheels.

Step 3: remove the brake caliper from the pillar components. Then use a flat chisel and a hammer to remove grease. Remove the cotter pin nut and loosen the castle. Wheel load components are free now, can be removed from the shaft. Ocean shipping loose bearing and washer, can be easily removed.

Step 4: pouring down the old oil seal carrier component. This can be achieved by using a screwdriver or lever manipulation of used oil seal. Thoroughly clean the wheel yi components. The relative side of the components in the valley of wheel will have two visible fixed notch, separated by 180 degrees.

Step 5: on a creasing insert a small punch, and then gently tap with a hammer. Repeat this process on the opposite impression, until completely removing the car wheel bearings race. Be careful not to cause any indentation or burrs, because it can interfere with new bearing suite installed correctly. Perform the same steps on the opposite wheel, in order to remove the two wheel bearing.

Step 6: use hydraulic press install new car wheel bearings race. Sure to use the correct size of the clamp sleeve or socket. If you don't have a hydraulic press, punch or socket and can use a hammer head of peace. These should be very careful to use so that the cone axis area will not be scratched or damaged, because this will lead to high, will damage the new car wheel bearings race in installation.

Step 7: a small amount of oil in the palm of your hand, then use your other hand holding the car wheel bearings. The car wheel bearings type new grease, ensure that the bearing cage and rollers surrounded on the entire circumference of the new bearing grease. To the rest of the grease extrusion wheel cover, insert the lubrication of the bearing wheel, tap until its meshing correctly. It will wheel over, install the new bearing and washer in the round.

Step 8: install the wheel load components to the fixed nut and screw down the shaft. This will correct the car wheel bearings load. Gradually turn the wheel at the same time in the tight fixed nut yi components. When bearing on tighten started bonding, slightly loosen the nut, until the bearing again to rotate, and then let the related wrench or lever down on its own. Bearing pre-load now conform to the required preloading. To install new split pin and reinstall the grease or dust cover.

Step 9: to remove the reverse order to install all of the components. Ensure that all related components before installation clean, especially all the fixed bolt. Apply the same process step by step to change relatively car wheel bearings.

Step 10:Reinstall the wheels of the vehicle, and on the brake pedal several times, to ensure that all relevant parts to readjust and focus themselves.Remove the bracket and the vehicle down to the ground. Tighten all the fixed wheel nut.Helpful hint 1: it is recommended that replace the wheel bearing on either side of the shaft at the same time. This ensures that the car wheel bearings wear, but at the same level of operation.

Useful hint 2: after replace the car wheel bearings, be sure to test drive your vehicle. This will ensure that all related components running within the required specifications.Useful tip 3: it is recommended that check wheel alignment after changing the car wheel bearings. This will ensure that all safety critical components running balance each other.

Welcome to contact me to get the price of car wheel bearings!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.