First, the classification of ceramic speed bearing

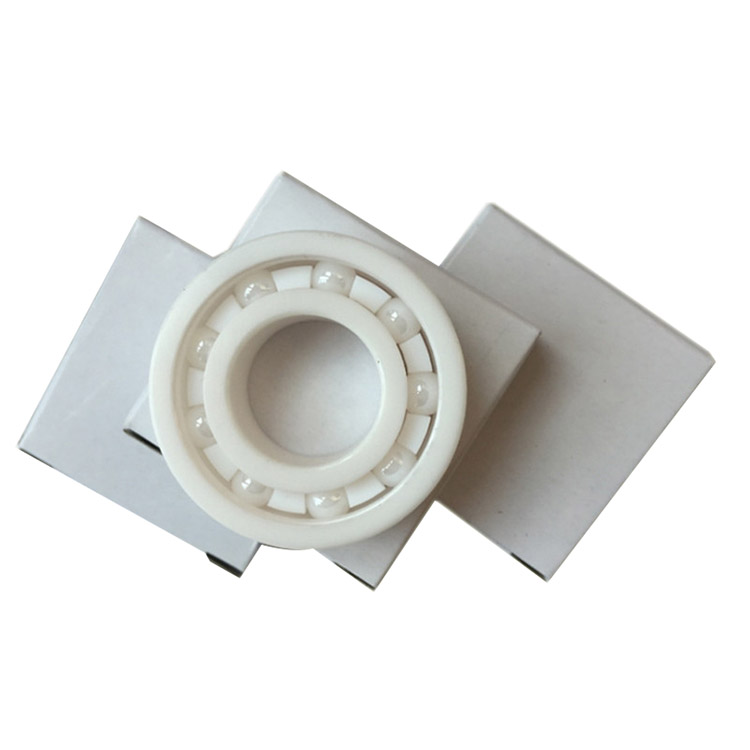

Ceramic ball high-speed bearings can be mainly divided into hybrid ceramic speed bearing and full ceramic speed bearing, of which all-ceramic ball high-speed bearings mean that the bearing inner and outer rings and rolling elements are all made of ceramic materials. Hybrid ceramic ball high-speed bearings only rolling element parts are made of ceramic materials, while hybrid ceramic ball high-speed bearings can be divided into the following three types according to material classification:

1. The ball and inner ring are ceramics, while the outer ring is metal;

2. Ceramic materials for balls, while the rest are still made of metal materials;

3. The ball and outer ring are ceramics, and the inner ring is metal.

Second, the performance characteristics of ceramic speed bearing

1. The elastic modulus is too large to reduce the bearing capacity of the shaft lining due to stress concentration.

2. Due to the reduction of the rolling element density of ceramic ball high-speed bearings, the centrifugal load of high-speed work is also reduced, so that it can work at higher speeds, and less heat is generated.

3. High compressive strength is the need for rolling bearings to withstand high stress, and for ceramic ball high-speed bearings, its strength can be determined by the modulus of fracture measured by the three-point or four-point bending test.

4. Reduce the sensitivity to temperature changes, so that the working temperature range of ceramic ball high-speed bearings is wider.

5. It has good resistance to rolling contact fatigue and has a spalling failure mode, which is important for the rolling element requirements of ceramic speed bearing.

6. In order to ensure that the bearing can maintain precise dimensions and accurate matching in the working environment of temperature changes, the bearing has dimensional stability at different temperatures.

7. In special occasions, it also has high temperature resistance (in a high temperature environment of up to 800 °C can stably maintain its mechanical properties), corrosion resistance (in oxidation and corrosion environment, especially in the contact zone of repeated rolling and squeezed out the surface oil film should have oxidation resistance and corrosion stability), decomposition resistance.

8. The combination of high hardness and high toughness can obtain better surface roughness, and can effectively prevent the damage of external particles and impact.

The above is the classification and performance characteristics of ceramic ball high-speed bearings full content, after the above introduction can be seen that ceramic ball high-speed bearings are mainly divided into hybrid ceramic ball high-speed bearings and all ceramic ball high-speed bearings, the bearing has low density, medium modulus of elasticity, small coefficient of thermal expansion, high compressive strength, high hardness and toughness and other performance characteristics, is widely used in a variety of high-precision, automobile, aero-engine, metallurgical machinery, high-speed machine tools and other fields. we produces a complete range of ceramic speed bearing, quality assurance, if you have any needs, please call at any time.

Welcome to contact me to get the price of ceramic speed bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.