It is not necessary to use ball linear bearings, but copper or cast iron bushings can also be used. In addition, there are self-lubricating (containing oil or graphite) bushings. Self-lubricating bushings at low and medium speeds do not require additional grease or lubricant. The bushing needs to be filled with grease or oil. However, sliding type sleeves are prone to generate gaps and heat when running for a long time or at high speed, which is an important disadvantage.

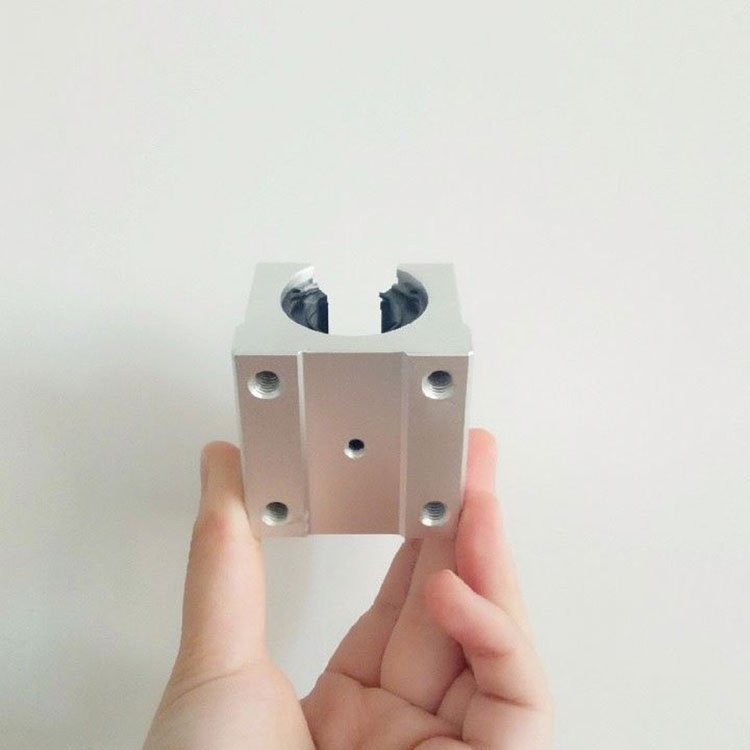

How to choose circular linear bearing:

1) High positioning accuracy

When the circular linear bearing is used as a guide, since the friction mode of the linear guide is rolling friction, not only the friction coefficient is reduced to 1/50 of the sliding guide, but also the gap between the dynamic friction force and the static friction force becomes small. Therefore, when the load platform moves, there will be no slippage and high positioning accuracy can be achieved.

2) Reduce wear and maintain high accuracy for a long time

Traditional circular linear bearing guide rails inevitably result in poor platform movement due to the oil film countercurrent effect, and due to insufficient lubrication during movement, the wear of the running track contact surface will affect the accuracy. The wear of the circular linear bearing guide is very small, so the equipment can maintain high accuracy for a long time.

3) Suitable for high-speed motion and drastically reduces the driving power required by the equipment

Because the frictional force when the circular linear bearing moves is very small, only a small force is required to make the load platform move, especially when the equipment works in a regular reciprocating motion, which can significantly reduce the equipment power loss. And because the heat generated by its friction is small, it is suitable for high-speed movement.

Linear sliders can be divided into: roller linear guides, circular linear bearing guides, and ball linear guides. They are used to support and guide moving parts and perform reciprocating linear motions in a given direction. Depending on the nature of the friction, linear motion guides can be classified into sliding friction guides, rolling friction guides, elastic friction guides, and fluid friction guides.

Linear sliders can be divided into: roller linear guides, circular linear bearing guides, and ball linear guides. They are used to support and guide moving parts and perform reciprocating linear motions in a given direction. Depending on the nature of the friction, linear motion guides can be classified into sliding friction guides, rolling friction guides, elastic friction guides, and fluid friction guides.

Welcome to contact me to get the price of circular linear bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.