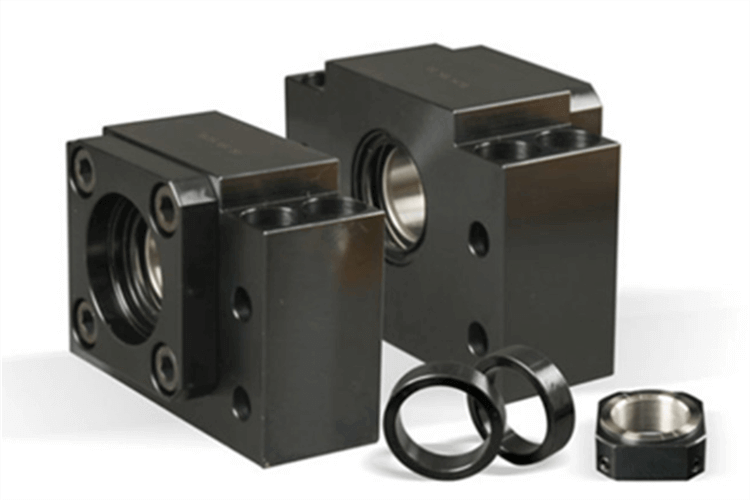

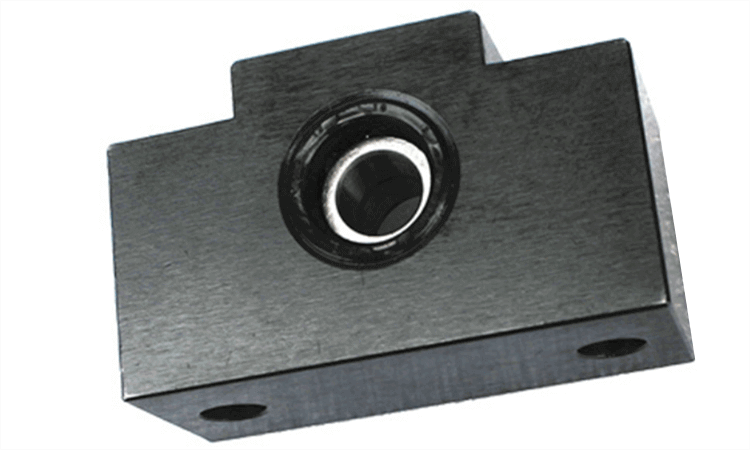

cnc ball screw assembly is the most commonly used transmission component in tool machinery and precision machinery. Its main function is to convert rotary motion into linear motion, or to convert torque into axial repetitive force, with high precision and reversibility. High efficiency features. Due to its low frictional resistance, cnc ball screw assembly is widely used in a variety of industrial equipment and precision instruments.

The cnc ball screw assembly consists of a screw, a nut, a steel ball, a pre-pressing piece, an inverter, and a dustproof device. Its function is to transform the rotary motion into a linear motion. This is the further extension and development of the Acme screw. The significance of this development is to change the bearing from a sliding motion to a rolling motion.

1. cnc ball screw assembly has low friction loss and high transmission efficiency

Since there are many balls between the screw shaft of the cnc ball screw assembly and the screw nut for rolling motion, high motion efficiency can be obtained. Compared with the past sliding screw pair, the driving torque is less than 1/3, that is, the power required to achieve the same motion result is 1/3 of the sliding screw pair. It is very helpful in saving electricity.

2, cnc ball screw assembly has high precision

Cnc ball screw assembly is generally produced in the world's highest level of mechanical equipment, especially in the factory environment for grinding, assembly and inspection, and strict control of temperature and humidity, due to the perfect quality management system. The accuracy is fully guaranteed.

3, cnc ball screw assembly high-speed feed and micro-feeding possible

Since the cnc ball screw assembly uses the ball movement, the starting torque is extremely small, and there is no creep phenomenon like sliding motion, which ensures accurate micro feed.

4, cnc ball screw assembly has high axial stiffness

Cnc ball screw assembly can be added with pre-compression, because the pre-pressure can make the axial clearance reach a negative value, and then get higher rigidity (by adding pressure to the ball in the ball screw, when it is actually used for mechanical devices, etc., The repulsive force of the ball can increase the rigidity of the silk mother.

5, cnc ball screw assembly can not be self-locking, with the reversibility of the transmission

ZYSL company specializes in cnc ball screw assembly for many years. All raw materials and accessories have been carefully selected to ensure a good user experience.

Welcome to contact us!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.