The spindle of CNC milling machine and CNC lathe is the most important component that affects the rigidity and accuracy of the machine tool. The quality of the spindle depends on the layout structure and installation method of the internal spindle cnc milling bed bearings. Let me share with you the layout, configuration and adjustment methods of spindle bearings.

1. Configuration and preloading of angular contact ball bearings on the spindle cnc milling bed bearings

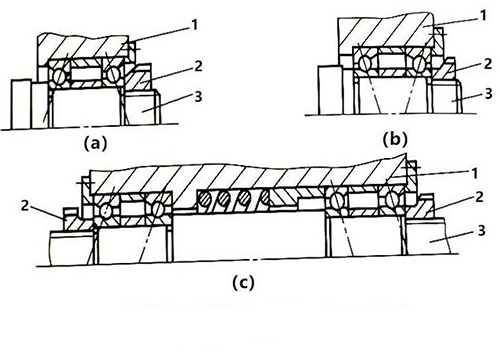

1. Angular contact ball bearings are usually arranged. There are three types of arrangements for angular contact ball bearings: (1) Back-to-back arrangement, with wide sides facing each other. (2) Face-to-face arrangement, that is, the narrow sides face each other. (3) Back-to-back arrangement in pairs in the same direction, that is, back-to-back in pairs.

Among them, the contact angle of the back-to-back arrangement of cnc milling bed bearings spreads along the axis of rotation. Therefore, the radial and axial rigidity is increased, and the deformation resistance is greater. It is the most commonly used bearing arrangement form.

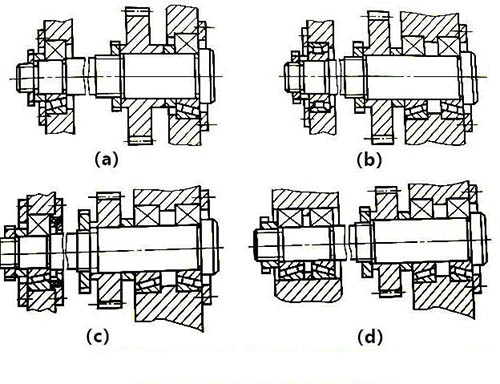

2. Configuration and adjustment of tapered roller bearings on the main shaft

1. Tapered roller bearings are commonly arranged on the main shaft. Tapered roller bearings are usually arranged in four forms on the main shaft: ①The structure of placing a bearing on the front and rear of the main shaft. ②The front end of the main shaft is equipped with two bearings back to back, and a cylindrical roller bearing is placed at the back end. ③The front end of the spindle is equipped with two bearings back to back. A bearing is installed at the rear end, and the outer ring is pressed by several springs to eliminate the gap. ④Two bearings are installed at the front end of the main shaft and fixed in the axial direction. Two bearings are installed at the rear end, and the outer ring allows axial movement.

Three, other types of cnc milling bed bearings assembly adjustment characteristics

①Deep groove ball bearings are widely used. When installing, pay attention to the selection of matching relationships. After assembly, there should be no gap or only a small amount of preload between the ball and raceway of the bearing.

②When installing thrust ball bearings or two-way thrust ball bearings, be careful not to skew the bearing surface of the bearing seat. Thrust ball bearings are usually arranged in pairs, and most of them must be preloaded. The pressing force should be so large that when the maximum axial load occurs, the elastic deformation of the loaded cnc milling bed bearings will not affect the static ring of the other bearing to follow the rotation without load. It should also be noted that the static ring and the moving ring cannot be reversed during installation. There is a transition fit between the inner hole of the moving ring and the shaft, and there is a gap of 0.20.3mm between the inner hole of the static ring and the shaft.

③After the tapered hole spherical roller bearing is installed on the main shaft, the inner ring of the cnc milling bed bearings is moved axially along the tapered journal through the nut to realize the radial clearance adjustment of the bearing. The adjustment nut should be controlled according to the principle of not only meeting the accuracy requirements of the spindle, but also keeping the temperature rise of the cnc milling bed bearings low, otherwise, check the taper error at the spindle journal or replace the new bearing.

Welcome to contact me to get the price of cnc milling bed bearings!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.