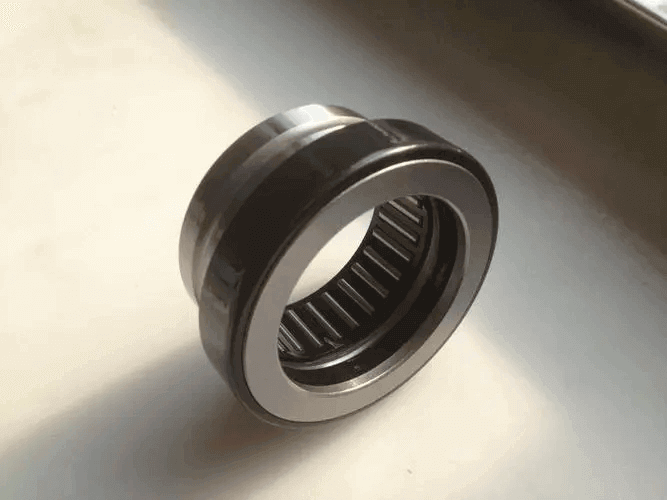

The combined bearing will heat up after starting to run, and after a period of time, it will be at a lower temperature (usually 10-40 degrees higher than room temperature). The time to normal state varies depending on the size, form, rotation speed, lubrication method of the combined roller bearings, and the heat release conditions around the imported bearing.

At this time, it takes about 20 minutes to several hours. When the bearing temperature does not reach the normal state and abnormal heating occurs, the following reasons can be considered. In addition, the shutdown should be stopped as soon as possible and necessary countermeasures should be taken.

Temperature is critical to maintaining proper life of imported bearings and preventing deterioration of lubricating oil, etc. It is recommended that:

It is best to use it in a non-high temperature state (generally below 100 degrees). The main cause of abnormal temperature rise Too much or too little lubricating oil.

Poor installation of combined roller bearings. The internal clearance of the combined bearing is too small, or the load is too large.

Excessive seal friction.

Lubricant does not match.

Creep of mating surfaces.

Secondly, check the raceway surface of combined roller bearings, the condition of the rolling surface and the joint surface, and the wear condition of the standoff for damage and abnormal conditions, especially the running track of the raceway surface.

To determine whether combined roller bearings can be used again, it is necessary to consider the damage level of the combined bearing, mechanical performance, priority, operating conditions, inspection cycle, etc. before making a decision.

When replacing the combined bearing, the new bearing should be carefully inspected, and the shaft diameter, bearing seat hole and rotor should be carefully inspected. When assembling and disassembling combined roller bearings, strictly implement the maintenance process and operate carefully to avoid improper assembly and disassembly. The bearing is damaged and the oil is refueled on time to ensure that the working condition of the bearing is always in good condition; carefully check the operation of the combined bearing, and find hidden troubles and eliminate them in time.

Welcome to contact me to get the price of combined roller bearings!

Contact: Miya

Email: [email protected]

Skype: +8618363031398

MP/Whatsapp: +8618363031398

Wechat: 18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.