Note on the replacement of the cross roller slewing bearing: First of all, you must know the overall center of gravity of the upper part of the cross roller slewing bearing. Before changing, you must change the pitch angle of the boom or increase or decrease the balance weight to keep the center of gravity in the center of the cross roller slewing bearing. The upper and lower support points supported by the machine; unified command password to ensure that all jacks rise simultaneously; choose good weather without wind; choose at least 4 jacks with sufficient tonnage; take necessary safety protection measures to prevent cranes The tilt is unstable during the upper jacking process.

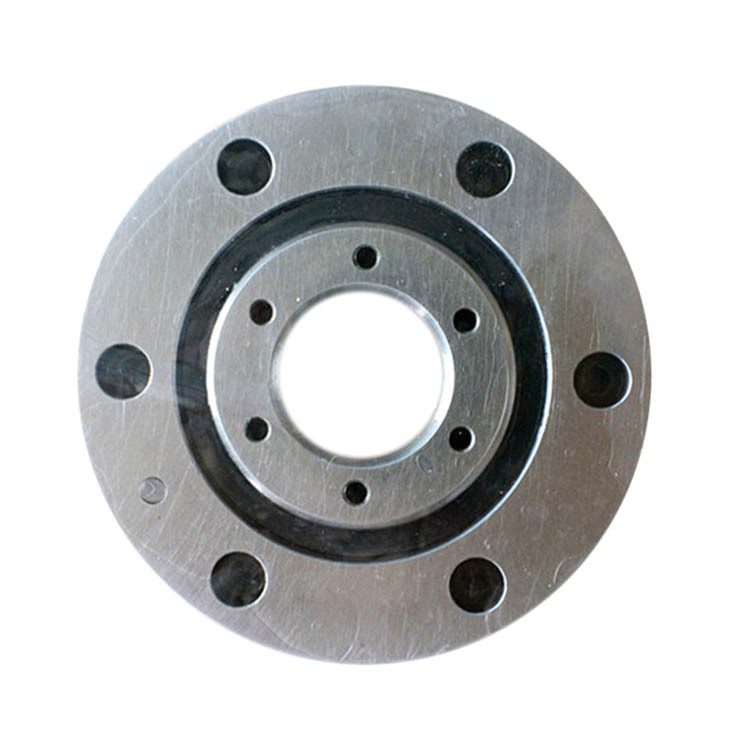

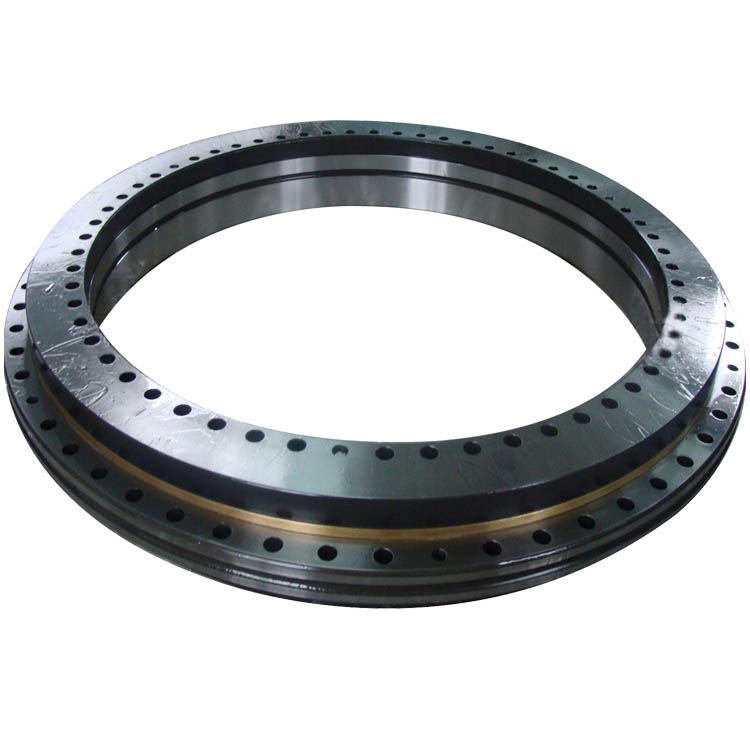

cross roller slewing bearing, the rollers of which are arranged at right angles to each other at intervals between the inner and outer wheels. They can withstand loads from all directions (such as axial, thrust or momentum loads). Since the roller is in contact with the surface of the track, the possibility of elastic deformation of the cross roller slewing bearing is small. This type of slewing bearing is widely used in industrial robots, work machines and medical facilities, and requires high rigidity and tightness. It is still possible to ensure precise conditions at high speeds.

In the cross roller slewing bearing, since the cylindrical rollers are vertically arranged by the spacers on the V-shaped groove rolling surface of 90°, one cross roller slewing bearing can bear the radial load and the axial direction. Loads in all directions, such as load and moment load. The size of the inner and outer rings is minimized, and the extremely thin type is a small size close to the limit and has high rigidity, so it is most suitable for the joint portion or the rotating portion of the industrial robot, the rotary table of the machining center, Uses such as robot rotating parts, precision rotary tables, medical equipment, gauges, and IC manufacturing equipment.

If you need the cross roller slewing bearing or other bearings, please contact me any time!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.