The material used for the metal solid cage is mainly brass, bronze alloy, but also cast iron and steel. Its structure mainly has two types: split type and integral type. The difference of the split type structure is mostly in the connection method; Improve the performance of cylinder cage bearing friction, operation and load.

Since the split cage needs to be integrated to realize the function, the split is mainly considered for the convenience of the process, and the split connection still has unreliable problems. Therefore, with the progress of process technology, the application of the integral cage will be more and more more.

One, split cage

1 . Split support riveted cage

The split type riveted cage is composed of a half cage, baffles and rivets, and is generally guided by rollers, as shown in the figure above. The half cage and the baffle plate are generally copper, and the rivets are generally made of low carbon steel. cylinder cage bearing of this structure are more commonly used, and have the advantages of low friction, low temperature rise, low noise, high strength, easy processing, etc., and are suitable for high speed and heavy load conditions. The disadvantage is that the presence of rivet holes weakens the strength of the cage, and improper riveting can cause loosening.

2 . Split self-riveting cage

The split self-riveting cage is composed of a half cage and a baffle plate. The end of the half cage beam has a riveted joint and a riveting hole on the baffle plate, which can realize self-riveting without the need for rivets, as shown in the above figure. The structure of the cage is similar to the split-type riveted cage. The technical principle and application characteristics are basically the same. The difference is the connection of the split cage.

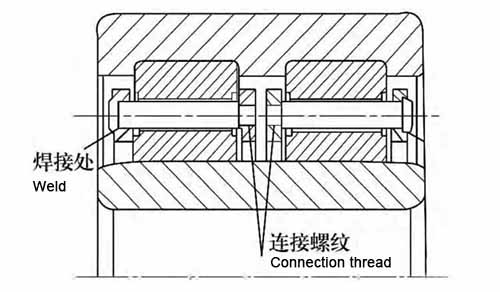

3 . Pillar type cage

The pillar-type cage of the cylinder cage bearing connects the cages together through the pillars, as shown in the figure above. One end of the pillar is threaded, one end is screwed on a cage retaining ring, passes through the hollow roller, and the other end is welded to the other cage retaining ring. Sometimes, in heavy-duty applications, both ends of the pillar need to be welded. When the cage is a pillar type design, the number of rollers that can be accommodated is large, and the load carrying capacity is high at this time. It is generally used for large cylinder cage bearing, such as rolling mill cylinder cage bearing.

Two: overall cage

1: Integral straight window hole cage

The structure of the integral straight window hole retainer is shown in the above figure. The cage is generally guided by the outer ring or the inner ring, and the straight window hole has a locking point to lock the roller. Compared with the split cage, the integral cage has higher strength and more reliable work, but the processing difficulty is relatively large, and the window hole generally needs to be broached.

2. Integral round angle window hole cage

The structure of the integral circular arc window hole cage is shown in the above figure. Because the inner surface of the lintel is a circular arc surface, it is convenient for roller guidance and lubrication, but it increases the difficulty of processing. This structure mainly avoids the interference between the corner of the pocket lintel and the roller, minimizes the stress concentration at the corner and facilitates lubrication.

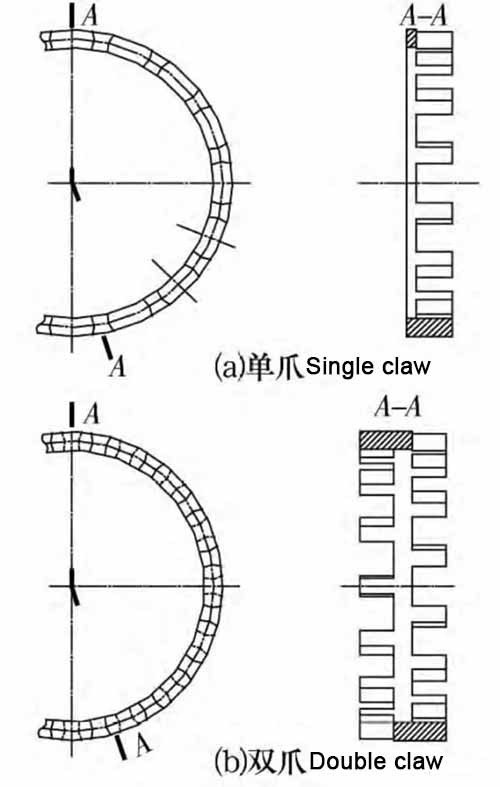

3. Double and four-row cylindrical roller bearing comb cage

The more commonly used cages for double and four-row cylinder cage bearing are single-jaw comb cages and double-jaw comb cages, as shown above. The double-claw comb-shaped cage can be loaded with 2 rows of rollers, and the two rows of rollers are alternately arranged; the single-claw comb-shaped cage requires two combinations, which is equivalent to a double-claw cage being cut radially. Small and medium-sized precision double-row cylinder cage bearing generally use single-jaw cages; double-jaw cages are generally used for large and medium-sized bearings.

Welcome to contact me to get the price of cylinder cage bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.