Features

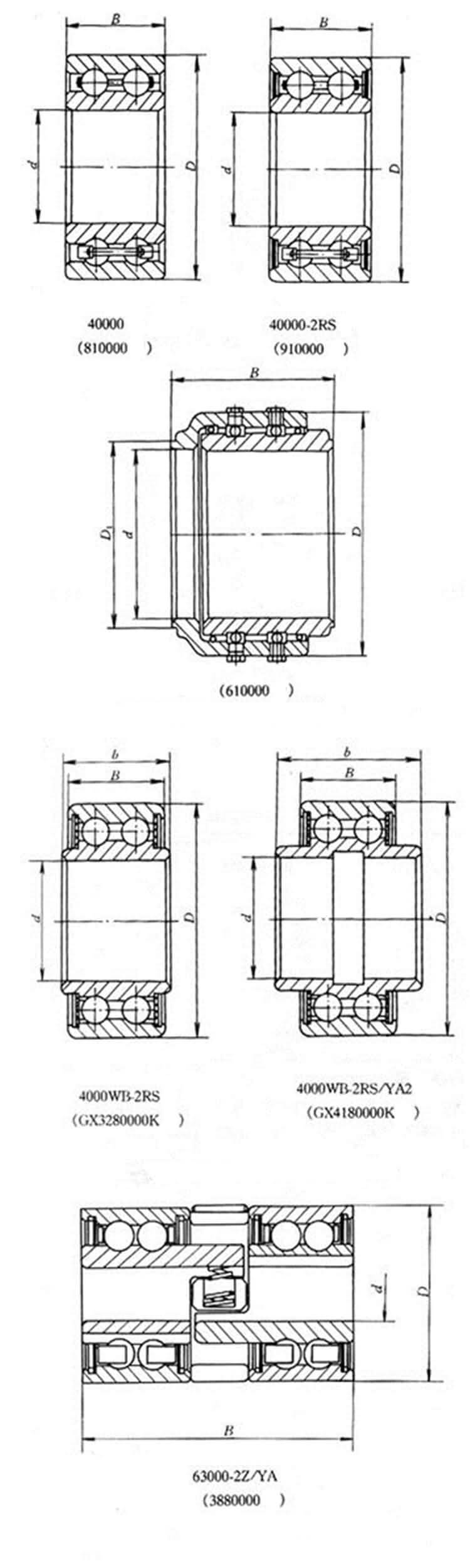

Double row ball bearing deep groove ball bearings are suitable for use in a single row deep groove ball bearing with insufficient load capacity. For the double row ball bearing with the same outer diameter and inner diameter as the deep groove ball bearings, the width is larger, and the load capacity is also much higher than that of 62 and 63 series single row deep groove ball bearings.

The standard deep groove ball bearings are common groups of radial internal clearances.

Alignment error

When there is centering error between the inner and outer rings of double row ball bearing, it will lead to additional load. This increases the load on the balls and cages and shortens the operating life of the bearings. Therefore, the allowable angular error is only 2 arc minutes. Any larger angle error will result in an increase in noise.

Cage

Double row ball bearing are equipped with two glass fiber reinforced nylon 66 cages. The SKF suffix is TN9.

Deep groove ball bearings with nylon cages can operate up to 120 °C.

The characteristics of the cage are not affected by the lubricants used for general rolling bearings, except for certain synthetic oils or greases based on synthetic oils and lubricants containing high levels of extreme pressure additives, except in high temperature applications.

Application editing

Minimum load

To get the bearings running well. Double-row ball bearing, like all ball bearings and roller bearings, must withstand a certain minimum load, especially at high speeds or high accelerations, or they can work quickly with changing load directions. Under these conditions, the inertia force of the ball and cage and the friction in the lubricant will have an adverse effect on the rolling of the bearing. There may be a damaging sliding motion between the ball and the raceway.

Use caution

In the case of starting at low temperature or where the viscosity of the grease is high, a larger minimum load may be required. The weight of the bearing, plus the external force, is usually exceeded by the minimum required load. If the minimum load is not yet reached, the bearing must be subjected to additional radial loads.

Axial load carrying capacity

If double row bearing is subjected to pure axial load, they should not exceed 0.5Co in general. Excessive axial load may significantly reduce the operating life of the bearing.

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.