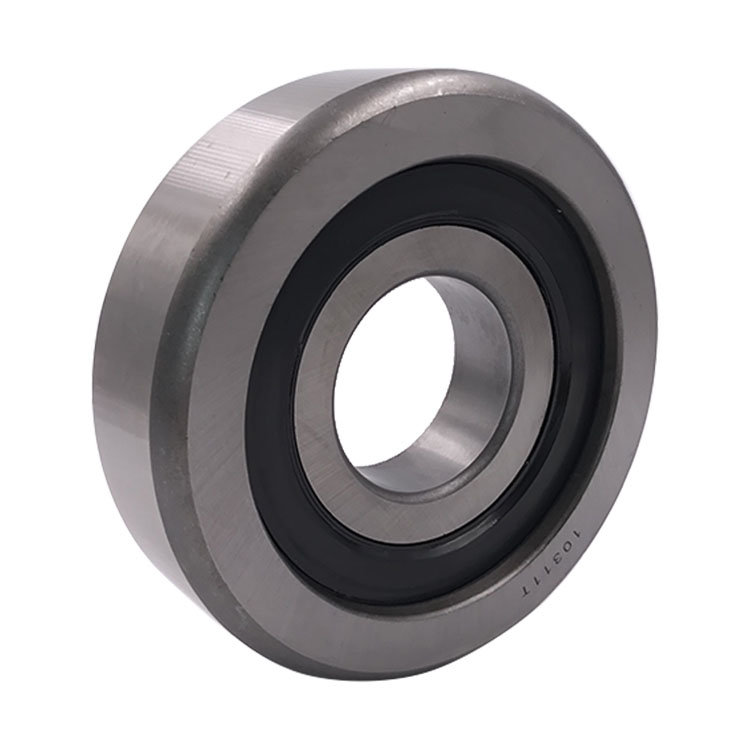

First, forklift mast roller bearings type

forklift mast roller bearings are a very important hardware component used in forklifts. Forklift bearings play an irreplaceable role in the work of forklifts. Below I analyze the bearing types in the entire forklift fitting.

Front axle of forklift: wheel bearing - angular contact ball bearing or deep groove ball bearing, tapered roller bearing, suspension bearing - thrust ball bearing, thrust needle roller bearing, steering gear bearing.

Forklift engine system: tensioner, idler bearing-bearing ball bearing, deep groove ball bearing, tapered roller bearing, clutch release bearing-ball bearing, water pump bearing-double row roller bearing and so on.

Forklift gearbox system: needle roller bearings, tapered roller bearings.

Other parts (body, door frame): gantry bearings, side roller bearings, etc.

Second, forklift mast roller bearings installation and installation matters:

1. Keep the forklift mast roller bearings and their surroundings clean. Even tiny dust that is invisible to the naked eye can enter the forklift bearing, which can increase the wear of the bearings of each system, or generate vibration and noise.

2.installation precautions

Strong stamping is not allowed when installing forklift mast roller bearings. It is not allowed to directly hit the forklift mast roller bearings with a hammer. It is not allowed to transmit pressure through the rolling elements.

3. Use appropriate and accurate installation tools

Try to use special tools and try to avoid using cloth and short fibers.

4.to prevent the corrosion of forklift mast roller bearings

When taking the forklift mast roller bearings directly by hand, we recommend that you thoroughly wash off the sweat from your hands and apply it with high-quality mineral oil before handling it. It is especially important to prevent rust during the rainy season and summer. However, under certain operating conditions, forklift mast roller bearings can achieve longer life than traditional calculations, especially at light loads. These special operating conditions are when the rolling surfaces (tracks and rolling elements) are effectively separated by a lubricating film and the surface damage caused by contaminants is limited.

If you need forklift mast roller bearings or other bearings, please contact me any time!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.