The guide rail bearing is an infinite rolling cycle of steel balls between the slider and the guide rail, so that the load platform can easily move with high precision along the guide rail and reduce the friction coefficient to one-fifth of the usual traditional sliding guide. Easily achieve high positioning accuracy.

Before installing the guide rail bearing, the burrs, dirt and surface scars on the mechanical installation surface must be removed.

Note: The guide rail bearing is coated with anti-rust oil before the formal installation. Please wash the reference surface with cleaning oil before installation. Usually, after the anti-rust oil is removed, the reference surface is easier to rust, so it is recommended to apply it Lubricating oil for spindle with lower viscosity.

The guide rail bearing installation steps are as follows:

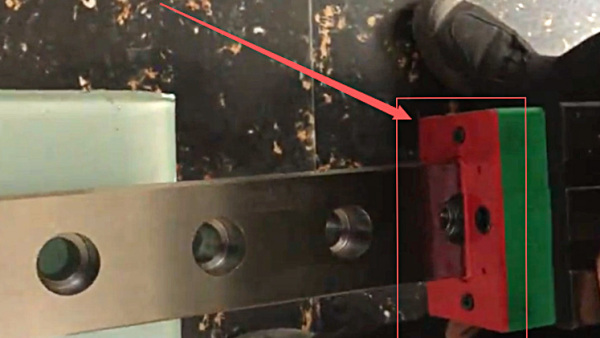

1. Align the guide rail bearing interface and push it gently to the place indicated by the arrow in the figure below.

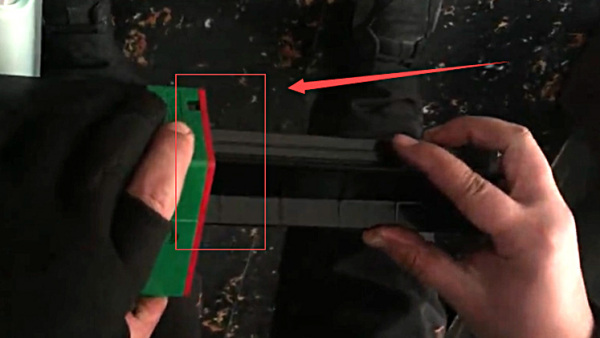

2. While pushing the slider, hold the tail of the slider with your hands behind your back. Eject the plastic block in the slider. The place pointed by the arrow in the figure below.

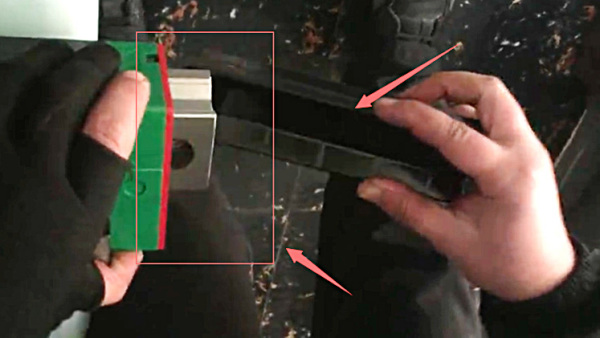

3. Until the plastic block falls off, the slider enters the guide rail completely, exposing the metal of the guide rail, and the installation is completed. The place pointed by the arrow in the figure below.

4. Push the slider back and forth several times, and test the guide rail bearing without blocking it is a success.

Note: If the tightening sequence of the assembly bolts is carried out diagonally, the workbench can be evenly fixed.

This method does not take time for adjusting the straightness of the linear guide rail bearing, and does not need to process positioning pins for fixing, so the installation man-hours can be greatly shortened.

In addition, different types of guide rail bearing have different installation methods. Such as circular rails.

Welcome to contact me to get the price of guide rail bearing!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.