As an important mechanical basic part, high temperature ceramic bearings have excellent performance that metal bearings can't match. High temperature resistance, super strength, etc. take the lead in the world of new materials. In the past ten years, high temperature ceramic bearings have been widely used in various fields of national economy and people's livelihood.

First, because high temperature ceramic bearings are almost not afraid of corrosion, ceramic rolling bearings are suitable for operation under harsh conditions full of corrosive media.

Second, because the high temperature ceramic bearings rolling ball has a lower density than steel and a much lighter weight, the centrifugal effect of the outer ring during rotation can be reduced by 40%, thereby greatly extending the service life.

Third, high temperature ceramic bearings are less affected by thermal expansion and contraction than steel. Therefore, when the bearing gap is constant, the bearing can be allowed to work in an environment where the temperature difference changes more drastically.

Fourth, because the elastic modulus of high temperature ceramic bearings is higher than that of steel, they are not easily deformed when subjected to force, which is beneficial to increase the working speed and achieve higher accuracy.

Main purposeedit

High temperature ceramic bearings have the characteristics of high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetic and electrical insulation, oil-free self-lubrication, and high speed. It can be used in extremely harsh environments and special working conditions. It can be widely used in aviation, aerospace, navigation, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textiles, pumps, medical equipment, scientific research, national defense and military fields. High-tech products for the application of new materials.

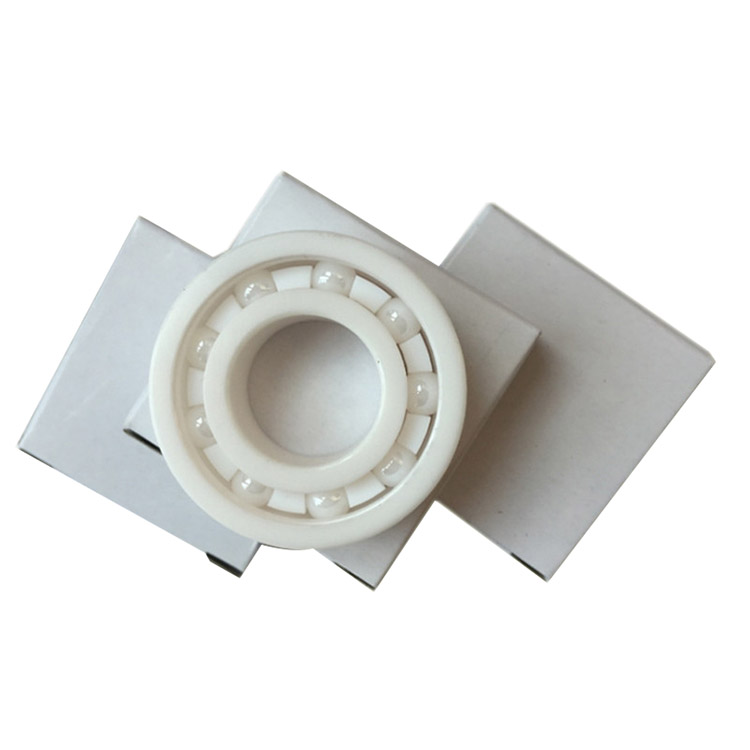

The rings and rolling elements of high temperature ceramic bearings are made of all-ceramic materials, including zirconia (ZrO2), silicon nitride (Si3N4), and silicon carbide (Sic). The retainer is made of PTFE, nylon 66, polyetherimide, zirconia, silicon nitride, stainless steel or special aviation aluminum, thereby expanding the application range of ceramic bearings.

With the continuous progress of processing technology and the increasing level of craftsmanship, the cost of high temperature ceramic bearings has continued to drop. From the past, they have been applied only in a small range of high, precise and cutting-edge fields, and have been gradually extended to various industrial fields of the national economy. The market price is gradually approaching practicality, reaching a level acceptable to users. The wave of large-area applications of high temperature ceramic bearings has surged!

Welcome to contact me to get the price of high temperature ceramic bearings!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: (86)18363031398

Wechat:18363031368

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.