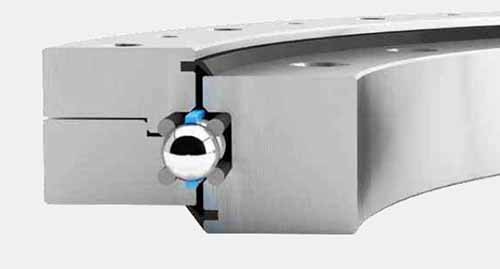

Used to drive the needle plate, cylinder and collecting mechanism of bearing is the biggest influence factors of knitting needle guide have a decisive influence on the quality of the finished fabric.Only when the machine can preciselyIn radial and axial guide knitting needle, to work out the perfect goods.Introduction of steel track knitting machine bearing is high-performance circular knitting machine design history an important development of great significance.

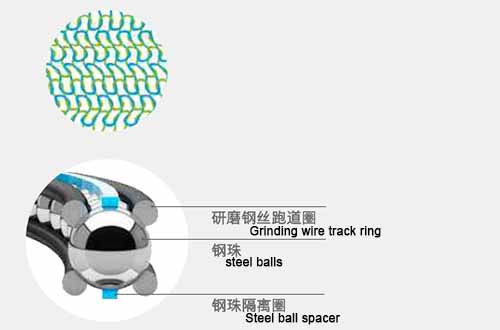

Steel track knitting machine bearing characteristic is a runway wire specially tempering treatment, at the same time ball bearings in the grinding or stretching exercise on the runway. The runway in coordinate structure directly. Close dimension can bring you great circle machine what other bearing solution does not have the new design of space.

Steel track knitting machine bearing in the field of circular knitting machine has the successful application of more than 50 years of history. The world's biggest mainstream knitting machine manufacturers are using Steel track bearing.

Ticket processing a thing, there are many kinds simple ways to choose. But the question is: do you use this knitting machine bearing produced by the loom performance and can produce the fabric quality to meet customer requirements?

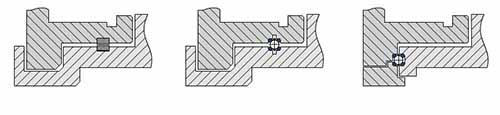

1. Wear-resisting pieces

Low price, unable to guide, low accuracy. when starting and stopping the vibration energy consumption high. Steel track knitting machine bearing perfect fabric quality is the guarantee the correct solution. Even if only for axial bearing, also can greatly improve the performance of the loom.

2. Copper wire will Franke cell bearing used for axial bearing

Easy to install, reduce energy consumption, smooth movement no vibration long service life. Steel track knitting machine bearingwith grinding track for a four-point contact ball bearing it as an ultimate solution, to ensure that the rotation of the circular knitting machine with perfect performance and work out the most superior quality fabrics.

3. For the four-point contact bearings

Easy to install, perfect working performance and accuracy. Ensure good quality of fabric, additive load is adjustable and can be adjust again. Very low energy consumption, long service life.

Welcome to contact me to get the price of knitting machine bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.