As our country pays more and more attention to the development of the machinery and equipment industry, it is an inevitable development trend to improve the machinery automation industry under the promotion of economic benefits. The technical level of linear guides and bearings for mechanical equipment accessories has also been improved to a large extent, and these are inseparable from the professional technical team of guide rail developers.

Linear guides and linear bearing pillow are common names of some people, generally refer to linear optical axes (including various flange linear bearing blocks), linear guide optical axes, linear circular guides (including linear guide bearing seat assembly sliding units and flange type Guide shaft support).

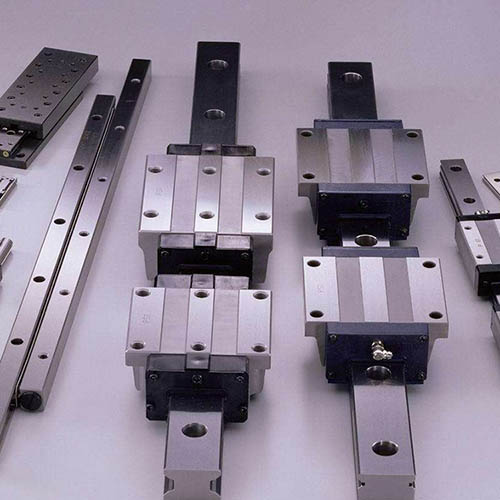

Linear guides and linear bearing pillow are basically two product accessories from the top. Linear guides are an accessory that transmits motion. The reciprocating linear motion from a specified point to the next point is a guide rail. The appearance of the linear guide bearing is obviously different from the outside of the linear guide: the guide shaft of the linear guide shaft bearing is in the shape of a round barrel; while the axis of the linear guide is a square structure.

The linear optical axis is a linear motion system, used in conjunction with linear bearing pillow and cylindrical shafts. Since the bearing ball is in point contact with the bearing jacket, the steel ball rolls with the least frictional resistance, so the linear optical axis has low friction, is relatively stable, does not change with the bearing speed, and can achieve smooth linear motion with high sensitivity and high accuracy. The consumption of the linear optical axis also has its limitations. The most important thing is that the linear bearing pillow has poor impact load capacity and poor carrying capacity; secondly, the linear bearing has greater vibration and noise during high-speed motion.

Linear guide bearings and linear guides have similar functions, both supporting and guiding. The main difference lies in the installation location: linear bearing pillow are generally fixed at both ends, and the suspended connecting parts in the middle cover all or most of the radial direction of the optical axis; linear guides are generally All one side is close to the equipment installation base and fixed with bolts.

Through the above detailed description, all manufacturers must have a deep understanding of linear guides as the core transmission component in automation.

Welcome to contact me to get the price of linear bearing pillow!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.