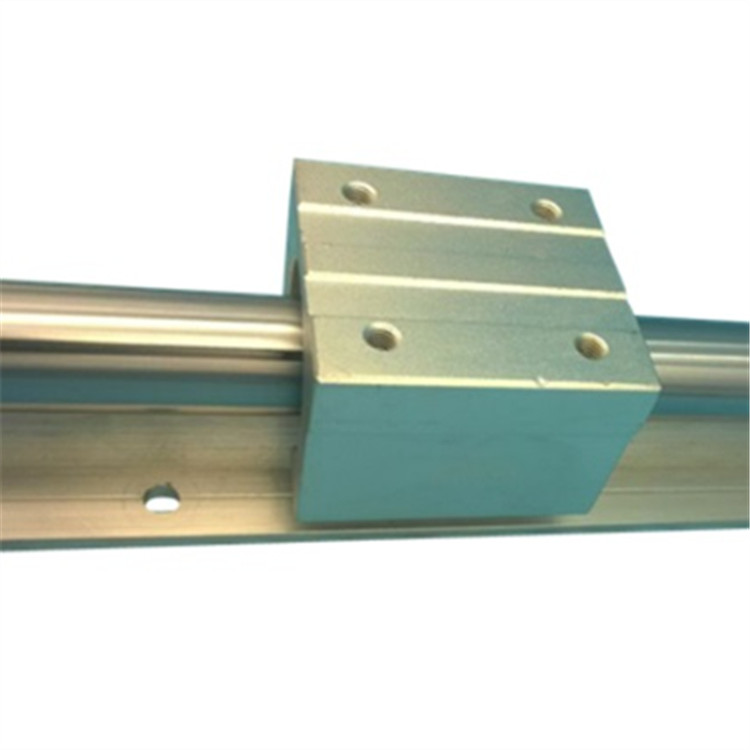

Linear guide rails and blocks- Transforms the motion from a curve to a straight line. The new guide system allows the machine to achieve fast feed speeds, which are characterised by linear guides at the same spindle speed. Linear guides, like planar guides, have two basic elements; One is oriented as a fixed element and the other is a moving element. Since linear guides are standard components for machine tool manufacturers. The only thing to do is to process the parallelism of a mounting rail plane and a calibrated guide. Of course, in order to ensure the accuracy of the machine tool, a small amount of scraping of the bed or column is indispensable, and in most cases, the installation is relatively simple. The guiding guide rail is hardened steel, which is finely ground and placed on the installation plane. Compared with the plane guide, the geometry of the cross-section of the linear guide rail is more complex than the plane guide, and the reason for the complexity is that the groove needs to be machined on the guide rail to facilitate the movement of the sliding element, and the shape and number of grooves depend on the function to be completed by the machine tool. For example, a guide rail system that is subjected to both linear and subverting moments, compared to a guide rail that only bears linear forces. There is a big difference in design.

The basic function of the fixing element (guide) of the linear guide rails and blocks system is like a bearing ring, a bracket for mounting the steel ball, and the shape of a "V" shape. The bracket wraps around the top and sides of the rail. To support the working parts of the machine, a set of linear guides has at least four brackets. For supporting large working parts, the number of brackets can be more than four.

When the working parts of the machine tool move, the steel balls circulate in the bracket grooves, and the wear of the bracket is distributed to each steel ball, thereby prolonging the service life of the linear guide rails and blocks. In order to eliminate the gap between the bracket and the guide rail, the preload can improve the stability of the guide rail system and obtain the preload load. It is to install an oversized steel ball between the guide rail and the bracket. The diameter tolerance of the steel ball is ±20 microns, in increments of 0.5 microns, the steel balls are screened and classified, and they are installed on the guide rails respectively, and the size of the pre-loaded load depends on the force acting on the steel ball. If the force acting on the steel ball is too large, the preload time is too long, resulting in increased resistance to the movement of the bracket, and the balance effect problem will occur; In order to improve the sensitivity of the system and reduce the resistance to movement, the preload should be reduced accordingly, and in order to improve the accuracy of motion and the retention of precision, it is required to have enough preload negative numbers, which are two contradictory.

Welcome to contact me to get the price of linear guide rails and blocks!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.