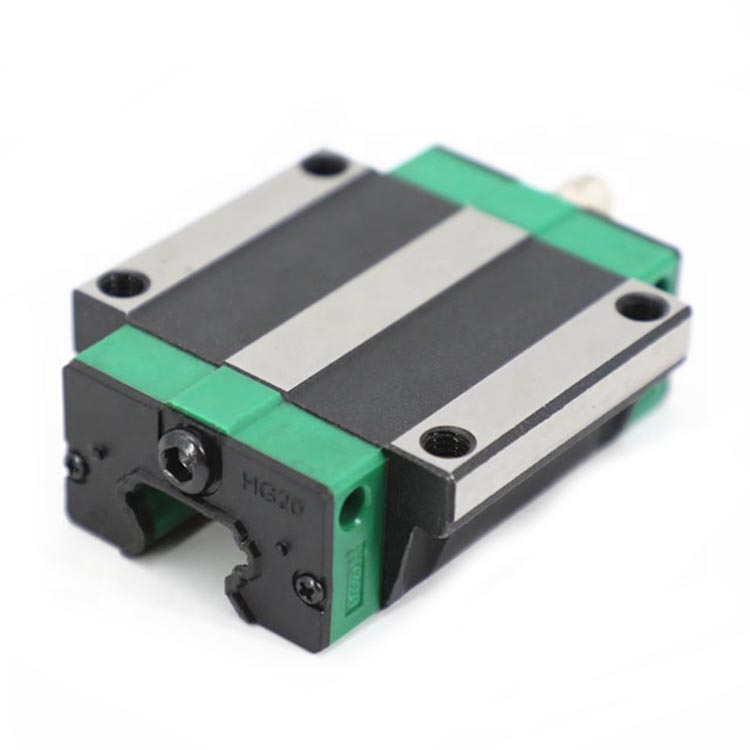

Everyone should know that linear slide rail bearings have many applications in machinery. In all kinds of machines, linear slide rail bearings can achieve maximum performance and achieve maximum economic benefits of automation and labor saving. The characteristics of linear bearings are lightweight, corrosion resistance, interchangeability, and low cost. However, many people do not know what preparations should be made before installing the linear slide rail bearings. What should be paid attention to during installation and use? Let's share with you the six installation steps of linear bearings.

1. The burrs, dirt and surface scratches on the mechanical mounting surface must be removed before the linear slide rail bearings. The linear slide rail bearings are coated with anti-rust oil. Please clean the reference surface with cleaning oil before installation. Usually, the reference surface is easy to rust after removing the anti-rust oil. It is recommended to apply the lubricating oil to the spindle with low viscosity.

2. Place the linear slide rail bearings on the bed gently and use a side fixing screw or other fixing fixture to gently fit the wire rail to the side mounting surface. Before installation, make sure that the screw holes are in agreement. If the working holes of the base are not matched and the bolts are forcibly locked, the combination accuracy and quality of use will be greatly affected.

3. Tighten the positioning screws of the linear bearing from the center to the sides in order, so that the rail fits the vertical mounting surface, and the tension from the center position to the both ends can obtain more stable precision. When the vertical reference surface is slightly tightened, the locking force of the lateral reference surface is strengthened, so that the linear slide rail bearings can be fitted to the lateral reference surface.

4. Using a torque wrench, tighten the set screws of the linear slide rail bearings to the shaft according to the various materials.

5. Install the sub-rails using the same installation method, and install the slides separately to the main rail and the sub-rail. Note that after the slider is mounted with the linear slide rails, many subsequent accessories cannot be installed due to limited installation space, and the required accessories must be installed at this stage.

6. Gently place the moving platform on the slide of the main slide and the secondary rail of the linear slide rail bearings, and then lock the lateral tensioning screws on the moving platform.

ZYSL company specializes in linear slide rail bearings for many years. All raw materials and accessories have been carefully selected to ensure a good user experience.

Welcome to contact us!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.