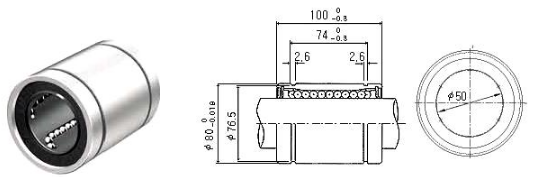

The structure and features of lm bearing

The lm bearing is composed of an outer cylinder, steel balls, steel ball retainers and buckles at both ends. The retainer is installed in the outer cylinder and is fixed by the buckles at both ends, so that the steel balls can circulate repeatedly on the track surface without falling off.

The outer cylinder of lm bearing has undergone sufficient heat treatment to achieve a considerable hardness to ensure safety and longevity during exercise. The steel ball retainer is formed by resin, which can reduce the noise and wear between the steel ball and the retainer. The allowable operating temperature is within 80°C.

1. High precision, high stiffness, low noise

The lm bearing has a high-hardness outer cylinder and steel balls, coupled with strict manufacturing requirements, so it has high precision; the use of high-tensile resin retainers reduces the amount of noise.

2. Easy to assemble

lm bearing can withstand loads in any direction, the products are standardized and standardized, and the matching components are easy to process, and it is easy to meet the requirements in assembly.

3. Product Type

Products include: standard type, gap adjustment type, open type, lengthened type and flange type lm bearing, which are convenient for customers to design and use. Linear bearing seat Linear bearing seat

The specialties of lm bearing:

Corrosion resistance and rust resistance linear bearing seat, shaft support seat, the material is aluminum alloy, the surface is electroplated after processing, not only the appearance is beautiful but also corrosive, and the shaft core is hard plated with chrome and does not rust and solid Has excellent anti-rust effect.

Easy assembly and interchange of lm bearing

Linear bearing housing products have been standardized, standardized, and strict accuracy requirements, so it is easy to meet customer requirements in terms of assembly or maintenance interchangeability.

The lm bearing runs smoothly and has low noise. The SC and SME series are sliding in contact with the shaft by linear bearings, with minimal frictional resistance. Therefore, it is very smooth and low noise during operation.

lm bearing has good economic benefits

lm bearing has the characteristics of light weight, corrosion resistance, interchangeability, low cost, etc., applied to various machine equipment, can exert the maximum performance, and achieve the maximum economic benefit of labor saving and automation. Compared with various types of slide rails, its cost is relatively low, and it has a price competitive advantage.

Welcome to contact me to get the price of lm bearing!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.