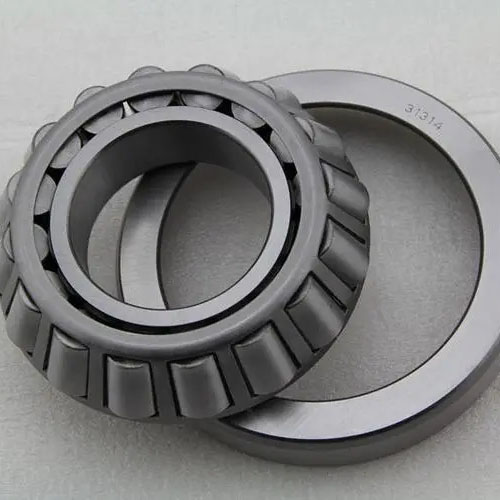

Definition of precision tapered roller bearing

Tapered roller bearings are separable bearings, and both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into different structural types such as single-row, variable-row and four-row tapered roller bearings according to the number of rows of rollers installed. Single row tapered roller bearings can withstand radial loads and axial loads in one direction. When the bearing is subjected to radial load, an axial component force will be generated, so when another bearing that can withstand axial force in the opposite direction is needed to balance it.

The ability of a single row precision tapered roller bearing to withstand axial loads depends on the contact angle, that is, the angle of the outer ring raceway. The larger the angle, the greater the axial load capacity. The most used tapered roller bearings are single row tapered roller bearings. In the front wheel hub of the car, a small-sized double-row tapered roller bearing is used. Four-row tapered roller bearings are used in heavy-duty machines such as large cold and hot rolling mills.

Structural characteristics of precision tapered roller bearing

The type code of the tapered roller bearing is 30000[1], and the tapered roller bearing is a separable bearing. In general, the outer ring and inner assembly of tapered roller bearings are 100% interchangeable, especially in the size range involved in GB/T307.1-94 "Rolling Bearings - Radial Bearings Tolerances".

The angle of the outer ring and the diameter of the outer raceway have been standardized as the outer dimensions. Changes during design and manufacture are not allowed. So that the outer ring and inner assembly of the tapered roller bearing can be interchanged worldwide.

precision tapered roller bearing are mainly used to bear combined radial and axial loads mainly based on radial loads. Compared with angular contact ball bearings, the bearing capacity is large and the limit speed is low. Tapered roller bearings can withstand axial loads in one direction and can limit the axial displacement of the shaft or housing in one direction.

precision tapered roller bearing application

Tapered roller bearings mainly bear the combined radial and axial loads mainly in the radial direction. The bearing capacity depends on the raceway angle of the outer ring, and the larger the angle, the greater the bearing capacity. This type of bearing is a separable bearing, which is divided into single-row, double-row and four-row tapered roller bearings according to the number of rows of rolling elements in the bearing. The clearance of single-row tapered roller bearings needs to be adjusted by the user during installation; the clearance of double-row and four-row tapered roller bearings has been given according to the user's requirements when the product leaves the factory, and does not need to be adjusted by the user.

precision tapered roller bearing have tapered inner and outer raceways with tapered rollers arranged in between. The projected lines of all conical surfaces meet at the same point on the bearing axis. This design makes tapered roller bearings particularly suitable for combined (radial and axial) loads. The axial load capacity of the bearing is mostly determined by the contact angle α; the larger the α angle, the higher the axial load capacity. The size of the angle is represented by the calculation coefficient e; the larger the value of e, the larger the contact angle, and the greater the applicability of the bearing to bear the axial load.

precision tapered roller bearings are usually separable, that is, the tapered inner ring assembly consisting of the inner ring with the roller and cage assembly can be installed separately from the tapered outer ring (outer ring).

Tapered roller bearings are widely used in automobiles, rolling mills, mining, metallurgy, plastic machinery and other industries.

Welcome to contact me to get the price of precision tapered roller bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.