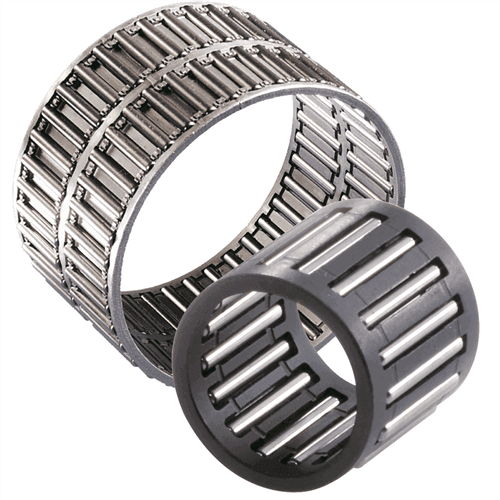

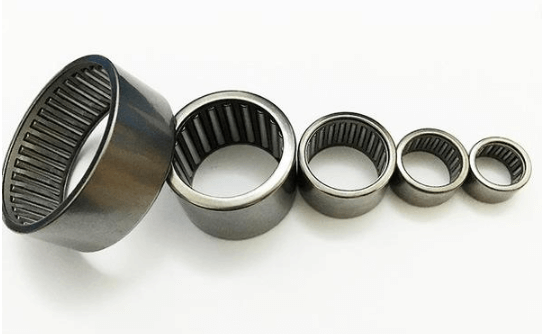

Choosing the right shaft and housing fit is very important for optimizing the performance and life of radial needle bearing. This article will discuss some key considerations in this field.

The radial needle bearing can exert its maximum performance only when it is correctly installed on the shaft and in the housing. On the contrary, improper bearing fit, too loose or too tight, will lead to poor operating conditions and early failure.

So, what factors need to be considered when choosing the fit of radial needle bearing? The following is a list of factors that bearer users need to pay attention to:

The direction, type and size of the load-calculate the equivalent radial load based on the actual axial and radial load. Generally speaking, as the load increases, a tighter fit is required. In addition, the ring radial needle bearing the circumferential load should have a tight fit. For rings that only bear point loads, loose fits can be used.inner ring or outer ring rotation-usually, the rotating ring needs an interference fit, and the non-rotating ring will have a slight loose fit.Specify the size and type of bearings-thin and miniature bearings are very sensitive to interference fits due to radial clearance losses. radial needle bearing with heavier cross-sections generally require a tighter fit.

Material and manufacturing tolerances of mating parts-fit tolerances are based on cast iron or steel housing and shaft. For alloys such as aluminum (with different modulus of elasticity), a tighter fit is required to achieve rigid seating.

Operating temperature-through the tight fit and the temperature difference between the inner and outer rings, the radial inner clearance in the radial needle bearing is reduced. This must be taken into consideration when selecting the internal clearance. In addition, if the materials used for the radial needle bearing seat or shaft are different, their thermal expansion coefficient will be different from that of the bearing ring. This must be taken into account in order to achieve a rigid seat.

Required operating accuracy-In order to achieve higher operating accuracy, the expected high accuracy and surface quality standards in the bearing must also apply to the shaft and housing. In addition, for miniature and thin bearings, irregularities on the shaft or bearing seat are transferred to the relatively thin bearing ring.

Welcome to contact me to get the price of radial needle bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.