Radial shaft seals with low profile heights, it is not easy to find commercial radial shaft seals for bearing arrangements with needle bearing or plain bearing bushings because of their very low profile height.

These contact seals do not have a clamping coil spring and are available in two designs:

– G design with single lip

– SD design with double lips

G design radial shaft seals

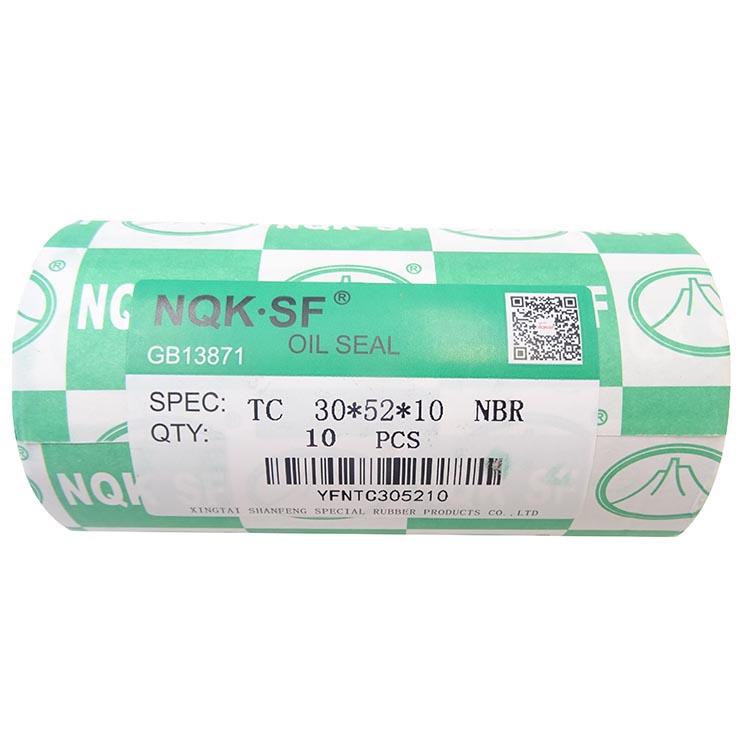

G design radial shaft seals are made of nitrile rubber (NBR). For seals with a shaft diameter of ≥ 8 mm, it is reinforced with steel plates. The rubber outer circumference enhances the seal along the seat hole, reducing damage to the seal and bushing during installation and removal.

For seals ≤ 7 mm, in order to obtain sufficient rigidity, the rubber material has a metal outer casing.

If the radial shaft seals are primarily used to hold the lubricant, install the sealing lip facing inwards. If the primary purpose of the radial shaft seals is to block contaminants, the sealing lip should face outwards and leave the bearing.

SD design of radial shaft seals

The SD design radial shaft seals have a primary sealing lip and a secondary dust lip. Both lips are made of a polyurethane elastomer (PUR), which is made of polyamide instead of metal.

The secondary lip is smaller and is designed for applications where the lip/shaft is not disturbed to avoid increased friction, heat generation and energy loss.

The main lip of the radial shaft seals, the larger one, is designed for contact sealing and should always point in the middle of the sealed portion. Therefore, if the main function is to block the entry of dust, the sealing lip should be outward. The secondary lip is responsible for maintaining the lubricant in the bearing arrangement.

In applications where the primary purpose is to maintain the lubricant, the primary lip should be facing inward toward the bearing.

The cavity between the two lips of the radial shaft seals should be filled with grease compatible with the lubricant used in the application. This will provide additional protection against the dry running of the radial shaft seals.

SDradial shaft seals are resistant to lubricating oils, even those containing small amounts of EP additives, and can withstand mineral oil based greases.

Depending on the mating surface of the shaft, SDradial shaft seals can also be used as a wiper seal for linear applications up to 3 m/s.

ZYSL company specializes in radial shaft seals for many years. All raw materials and accessories have been carefully selected to ensure a good user experience.

Welcome to contact me to get the price of radial shaft seals!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.