Radial bearings are bearings that are primarily subjected to radial forces.

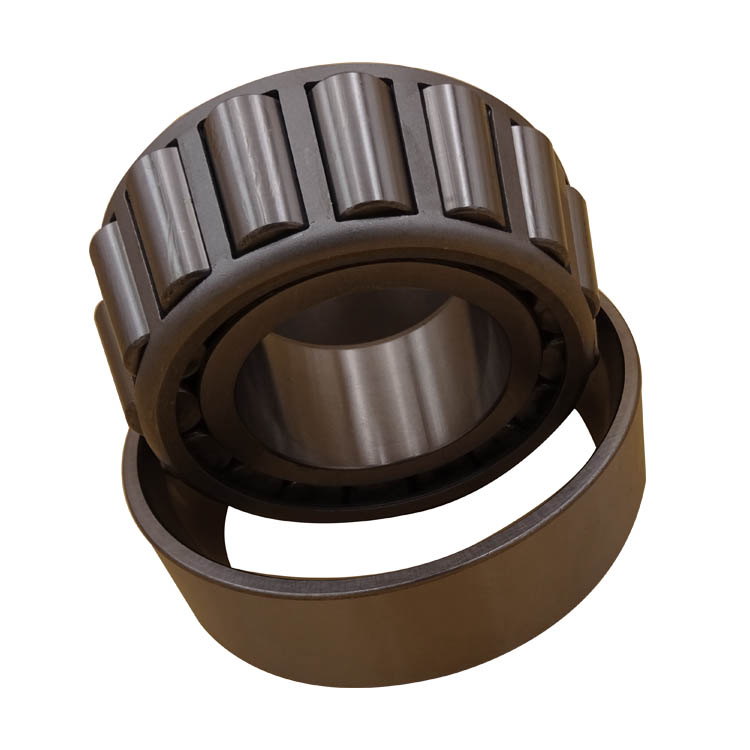

The composition of radial tapered bearing: The part of the shaft supported by the bearing is called the journal. The part that matches the journal is called the bearing bush. The part that is made into the full cylindrical shape is called the part of the shaft set bearing bush. The upper part is called the bearing cap. The lower part is called the bearing housing. The cover and the seat are coupled by a stud, and the joint faces of the two are positioned by a stop or a pin, and spacers of different thicknesses can be placed to adjust the bearing clearance. Most bearings have a joint surface that is horizontal and slanted to accommodate the load direction approaching perpendicular to the joint surface. In order to facilitate the entry of lubricating oil between the friction surfaces, the bearing cover is provided with an oil filling hole, and the bearing bush has an axial oil groove for distributing lubricating oil. The bearing cap and seat are mostly made of cast iron, and the load-bearing steel or steel plate welded structure is used.

Radial positioning of radial tapered bearing:

If the bearing capacity of the radial tapered bearing is to be fully utilized, the entire circumference of the bearing ring and the entire width of the raceway must be adequately supported. This support must be stable and uniform. For radial bearings, cylindrical or conical mounting faces can be used. Correspondingly, for the bearing rings and races of thrust bearings, a flat surface support can be used. This means that the bearing mounting surface must be machined with sufficient tolerances and that the surface must be free of grooves, holes or other similar discontinuities unless the mounting surface is ready for oil filling. It is very important for ultra-precision bearings that the bearing ring is relatively thin and tends to deform in accordance with the shape of the shaft or housing. In addition, the radial tapered bearing ring must be securely fixed to prevent it from rotating on the mounting surface (or in the load) under load.

In general, only the bearing ferrules have the proper interference after installation to achieve proper radial positioning and adequate support. In general, only the bearing ferrules have the proper interference after installation to achieve proper radial positioning and adequate support. The bearing ring is not securely fixed or incorrect, and it is easy to damage the bearing and its related parts. However, an interference fit is usually not available when the axial displacement is required (for non-locating bearings) or when it is convenient to install and disassemble. Once a clearance fit is required, but in most cases, an interference fit may be used, special precautions must be taken to reduce fretting wear due to creep (the ferrule is rotating on the radial tapered bearing mounting surface). For example, mounting the bearing. The surface and the shoulder are surface hardened.

If you want to buy radial tapered bearing or other ball & roller bearings, if you are interested in our bearings, please contact me, we will do the best for you!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.