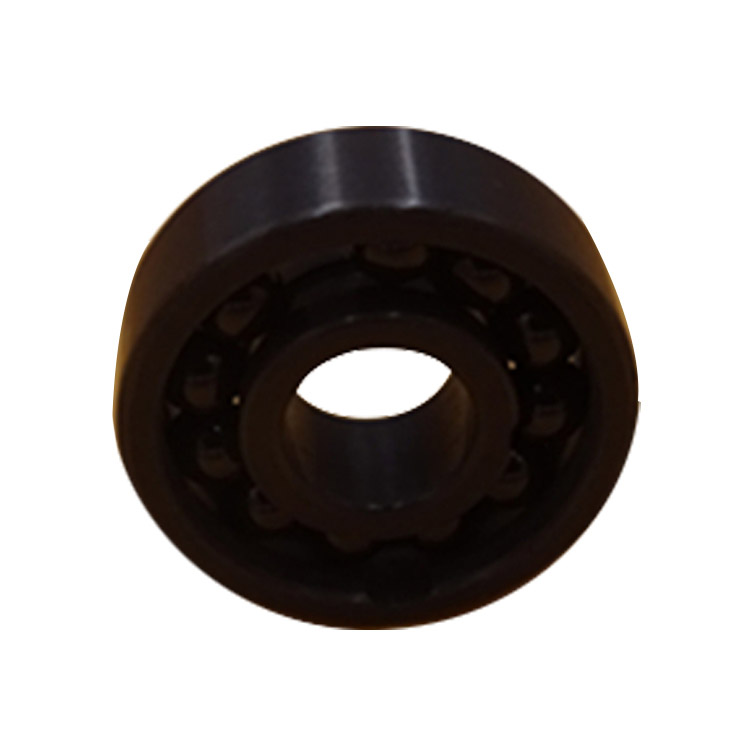

The structure of silicon nitride bearings:

All silicon nitride bearings ferrules and rolling elements are made of silicon nitride (Si3N4) ceramic materials. Generally, RPA66-25, PEEK, PI, and phenolic cloth bakelite pipes can also be used.

Compared with ZrO2 material, silicon nitride bearings can be applied to higher speed and load capacity, as well as higher ambient temperature. At the same time, it can provide precision ceramic bearings for high-speed, high-precision and high-rigidity spindles, with the highest manufacturing accuracy reaching P4 to UP.

Advantages of silicon nitride bearings:

a. Since ceramics are almost not afraid of corrosion, ceramic rolling bearings are suitable for operation under harsh conditions full of corrosive media.

b. Because the density of ceramic rolling balls is lower than that of steel, silicon nitride bearings are lighter, so the centrifugal effect of the outer ring during rotation can be reduced by 40%, and the service life is greatly extended.

c. Silicon nitride bearings are less affected by thermal expansion and contraction than steel. Therefore, when the bearing gap is constant, the bearing can be allowed to work in an environment where the temperature difference changes drastically.

d. Since the elastic modulus of silicon nitride bearings is higher than that of steel, they are not easily deformed when subjected to force, which is beneficial to increase the working speed and achieve higher accuracy.

Main uses of silicon nitride bearings:

Silicon nitride bearings have the characteristics of high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetic and electrical insulation, oil-free self-lubricating, and high speed. Silicon nitride bearings can be used in extremely harsh environments and special working conditions, and can be widely used in aviation, aerospace, navigation, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textiles, pumps, medical equipment, scientific research, national defense and military, etc. The field is high-tech products for the application of new materials.

Application areas of silicon nitride bearings:

Medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, food processing machinery, in aerospace, navigation, nuclear industry, petroleum, chemical, textile industry, machinery, metallurgy, electric power, food, locomotives, subways , High-speed machine tools, scientific research, defense and military technology and other fields need to work under special conditions such as high temperature, high speed, cryogenic, flammable, explosive, strong corrosion, vacuum, electrical insulation, non-magnetic, and dry friction.