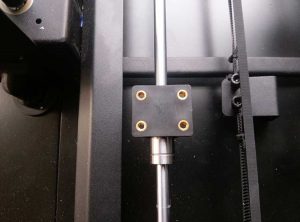

In actual production, slide bearing cnc drives the table mounted on it to make a linear reciprocating motion along the guide rail of the table body. The normal operation of slide bearing cnc directly affects the actual accuracy of the product and the quality of the product, so The daily inspection and maintenance of slide bearing cnc cannot be ignored.

However, the maintenance of slide bearing cnc has the problem of poor maintenance. The machine body is too large. Slide bearing cnc generally does stress exercise. There are inconveniences and frequent maintenance of manual maintenance, where many users of the machine will ignore maintenance.

In order to prevent the production delay caused by the damage of slide bearing cnc and high maintenance costs, and in order to better save labor resources, after continuous research and improvement, a product, called "rail automatic slider lubricator" was developed ".

The guide rail slider automatic oiler operates the small reducer according to the time stored in the microprocessor, drives the worm wheel inside the pump, and sucks / sprays the grease in the container through the reciprocating motion of the vertical piston.

1. Optional oil injection cycle. One-touch can choose 1, 2, 3, 6, 12 months and 15 days (half-month) injection cycle you want.

2. Set the date display function. The selected injection cycle and the current number of days of use are displayed for easy visual inspection.

3. Environmental friendly. As long as the grease and battery box are replaced, it can be used again, and fundamentally prevent environmental pollution.

4. Date display function of spray stop. Display the date of fuel injection stop for easy fuel supply management (with fuel injection date saving function).

5. Differential pressure diagnosis function. It shows that the oil supply is blocked due to excessive oil supply or excessive pressure such as pipeline resistance.

6. Test function. It is used for various purposes such as confirming operation, rapid fuel injection (clearing), and motor load diagnosis.

7. Reliability of grease supply. High working pressure (20kgf / cm2), suitable for long-distance installation.

8. Battery diagnosis function. Display battery capacity status and accurately inform replacement time.

9. Built-in LCD large screen, easy to read data, and provide all necessary information to optimize equipment monitoring. The easy-to-decode indicator on the LCD can help you easily understand the working status of the greaser and lubrication point

The appearance of the automatic oiler automatically solves the inconvenience and frequent maintenance, reduces the production delay caused by the damage of the rail slider in the production of the automatic oiler, and the high maintenance costs.