In order to maximize the service life of spherical plain bearings and rod ends without premature failure, it is important to pay attention to skill and keep them clean when installing. Bearings and rod ends should be installed in order to maximize the service life of spherical plain bearings and rod ends without premature failure, and must be installed with skill and cleanliness. Bearings and rod ends should be removed from the package only immediately before installation to avoid contamination. Bearing components that may be soiled due to improper handling or broken packaging should be wiped with a clean cloth. The sliding contact surfaces of spherical plain bearings and rod ends must be matched to ensure good friction and wear characteristics. Therefore, any change in the sliding contact surface can reduce bearing service life.

The above changes also include cleaning the sliding contact surface or exposing it to solvents, detergents, oils or similar media. All relevant parts should be kept clean and free of any burrs. At the same time, be sure to check the exact dimensions of the relevant parts before starting the installation program.

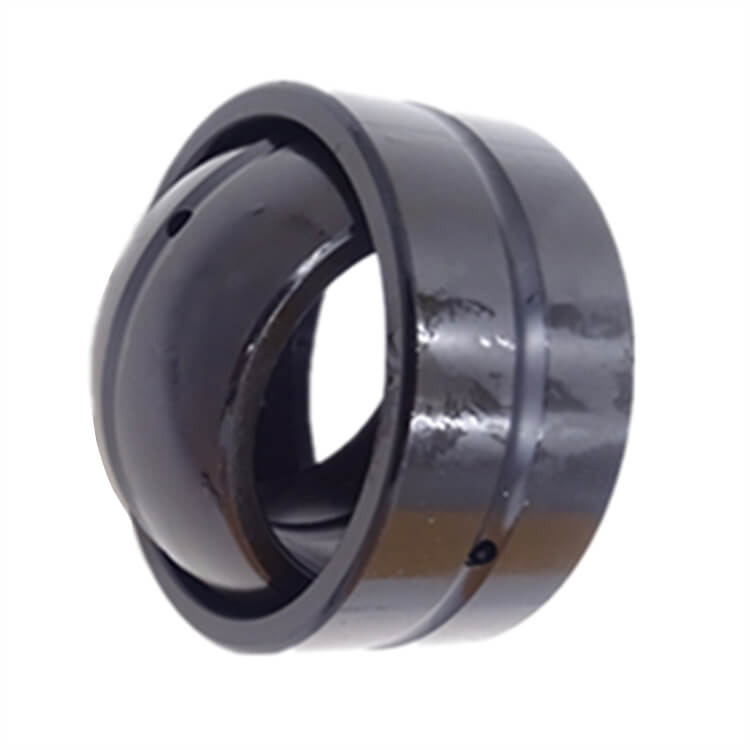

spherical plain bearings and rod ends

When mounting spherical plain bearings with cracked or split outer rings, take care that the joint is positioned at 90° to the direction of the load

The steel or plastic fastening straps used to secure the outer ring of spherical plain bearings must not be removed prior to installation. The fastening belt is located in the annular groove and does not protrude from the outer surface of the bearing. The outer ring of a spherical plain bearing that is axially split and bolted must be mounted in such a way that the bolts must not be loosened. , otherwise the service life will be shortened.

Rod end spherical bearings

Rod end shafts are equipped with pins and shafts like spherical plain bearings. A little heating reduces the required mounting force and reduces the risk of damaging the relevant components.

When fixing rod ends to threaded rods or extension tubes, countersunk lock nuts should be used on the external threads of rod or rod endings. The countersink lock nut should be tightened against the rod end bearing or the shoulder surface of the tube.

Welcome to contact me to get the price of spherical plain bearings and rod ends!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.