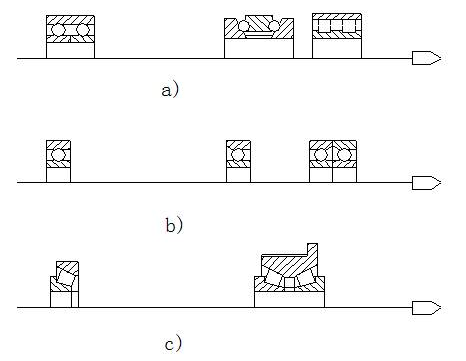

Figure 1 Spindle bearing cnc configuration form

1) The front support uses a combination of double row cylindrical roller bearings and double row 60o angular contact ball bearings, and the rear support uses paired angular contact ball bearings (Figure 1a). The spindle bearing cnc of this configuration greatly improves the overall rigidity of the spindle and can meet the requirements of powerful cutting, so it is commonly used in the spindles of various CNC machine tools.

2) Spindle bearing cnc uses high-precision double-row angular contact ball bearings (Figure 1b). Angular contact ball bearings have good high-speed performance, the maximum speed of the spindle can reach 4000r / min, but its load carrying capacity is small, so it is suitable for high-speed, light-load and precision CNC machine tool spindles. In the main shaft of the machining center, in order to improve the load-bearing capacity, the front support of the combination of 3 or 4 angular contact ball bearings is sometimes used, and the preload is realized by the spacer.

3) The spindle bearing cnc adopts double-row and single-row tapered bearings (Figure 1c). This kind of bearing has high radial and axial stiffness, can bear heavy load, especially strong dynamic load, and has good installation and adjustment performance. However, this bearing configuration limits the maximum speed and accuracy of the spindle, so it is suitable for medium precision, low speed and heavy duty CNC machine tool spindles.

With the development of the material industry, there is a tendency to use ceramic ball bearings in the spindle bearing cnc. The characteristics of this spindle bearing cnc are: light weight of ball, small centrifugal force, small dynamic friction torque; small thermal expansion due to temperature rise, which stabilizes the preload of the spindle; small elastic deformation, high rigidity and long life. The disadvantage is higher cost.

In the structure of the spindle, it is necessary to deal with the chuck or tool clamping, spindle unloading, spindle bearing cnc positioning and clearance adjustment, spindle assembly lubrication and sealing, and a series of technical problems.

In order to minimize the influence of thermal deformation caused by the temperature rise of the spindle assembly on the working accuracy of the machine tool, the circulation system of the lubricating oil is usually used to take away the heat of the spindle assembly, so that the spindle assembly and the box body maintain a constant temperature. In some CNC milling and boring machines, a special cooling device is used to achieve temperature control. In recent years, some spindle bearing cnc have been lubricated with advanced grease. Each grease can be used for 7 to 10 years, simplifying the structure and reducing Cost and simple maintenance. But to prevent the mixing of lubricating oil and grease, labyrinth seal is usually adopted.

For the CNC lathe spindle, because the power chuck and clamping hydraulic cylinder are installed at both ends of the spindle, the rigidity of the spindle must be further improved, and a reasonable coupling end should be designed to improve the coupling rigidity of the power chuck and the end of the spindle.

Welcome to contact me to get the price of spindle bearing cnc!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.