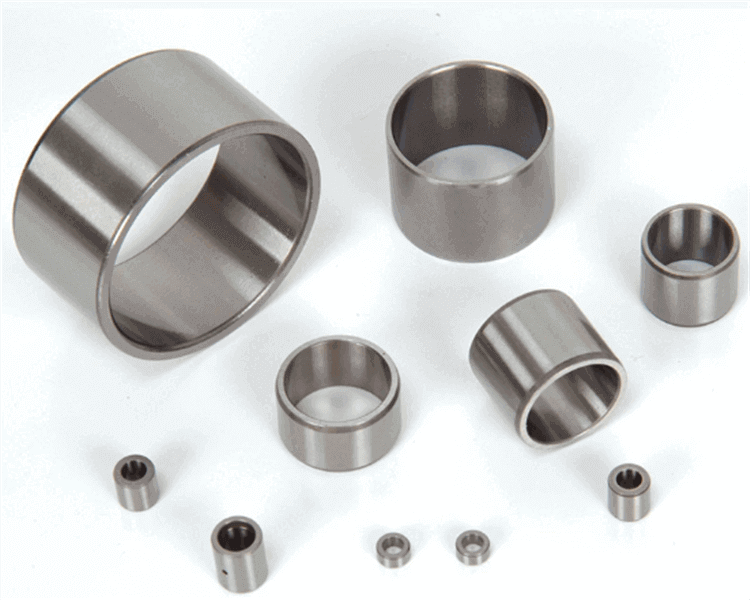

Materials of Steel sleeve bearings:

4) Special metal materials include structural metal materials and functional metal materials for different purposes. Among them are amorphous metal materials obtained by rapid condensation process, as well as quasi-crystal, microcrystalline, nanocrystalline metal materials, etc.; and special functional alloys such as stealth, hydrogen, superconductivity, shape memory, wear resistance, vibration damping and the like. , as well as metal matrix composites and the like.

4) Special metal materials include structural metal materials and functional metal materials for different purposes. Among them are amorphous metal materials obtained by rapid condensation process, as well as quasi-crystal, microcrystalline, nanocrystalline metal materials, etc.; and special functional alloys such as stealth, hydrogen, superconductivity, shape memory, wear resistance, vibration damping and the like. , as well as metal matrix composites and the like.

If you want to buy the steel sleeve bearings or other bearings, please contact me!

Contact:Miya

Email:[email protected]

Skype:[email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.