Adjusting the Axial Clearance For the installation of the taper bearing, the axial clearance can be adjusted by adjusting the nut on the journal, adjusting the washer and the thread in the bearing seat hole, or by means of a preloaded spring. The size of the axial clearance is related to the arrangement of the bearing during installation, the distance between the bearings, and the material of the shaft and the bearing seat, which can be determined according to the working conditions.

For taper bearing with high load and high speed, when adjusting the clearance, the influence of temperature rise on the axial clearance must be considered, and the clearance reduction caused by the temperature rise must be estimated. That is to say, the axial clearance should be properly Adjust it a little bigger.

For taper bearings with low speed and vibration, it should be installed without clearance, or installed with preload. The purpose is to make the taper bearing's roller and raceway have good contact, distribute the load evenly, and prevent the roller and raceway from being damaged by vibration and impact. After adjustment, check the axial clearance with a dial gauge.

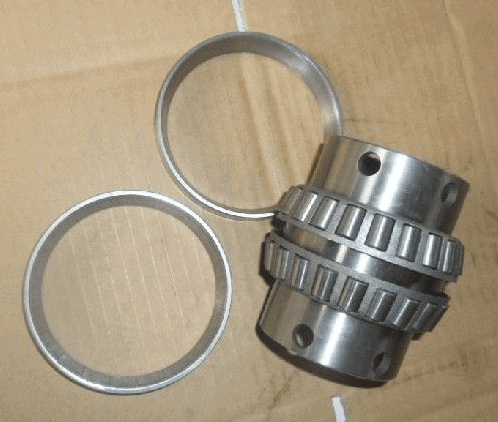

Installation of four-row taper bearing (installation of roller bearings):

1. The fit between the inner ring of the four-row taper bearing and the roll neck is generally with a gap. When installing, first put the bearing into the bearing box, and then put the bearing box into the journal.

2. The outer ring of the four-row taper bearing and the bearing box hole also adopt dynamic fit, first put the outer ring A into the bearing box. The outer ring, inner ring and inner and outer spacers are printed with the character symbol when they leave the factory. When installing, they must be installed in the bearing housing in the order of the characters and symbols. Can not be interchanged arbitrarily to prevent the change of bearing clearance.

3. After all parts are installed in the bearing housing, the inner ring and the inner spacer, and the outer ring and the outer spacer are axially close.

4. Measure the width of the gap between the end face of the outer ring and the cover plate of the bearing box to determine the thickness of the corresponding sealing gasket.

Multi-sealed bearings are marked with the post-code XRS.

If you need our taper bearings or other bearings,please contact me anytime~