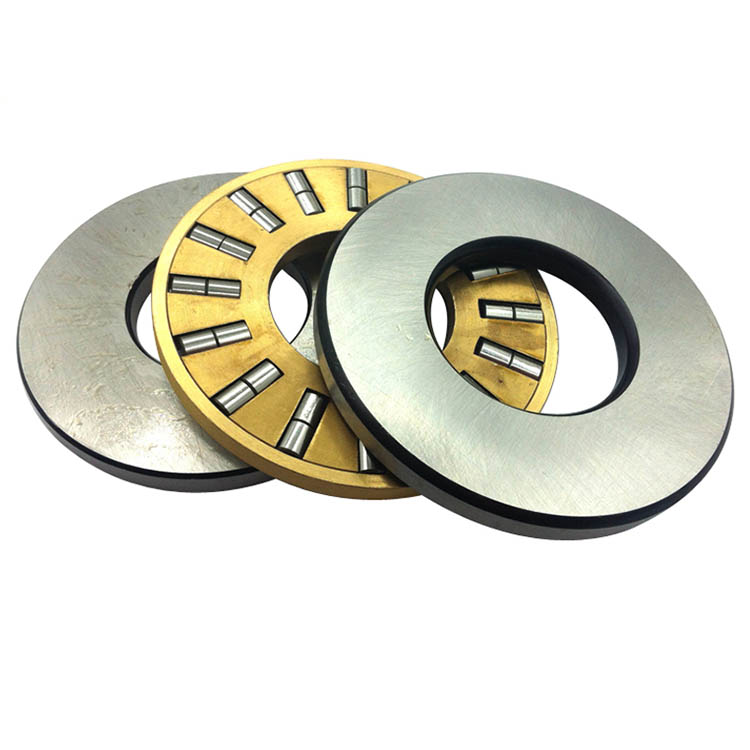

The thrust load bearing is a separate type of bearing, and the shaft ring and the seat ring can be separated from the components of the cage and the steel ball. The shaft ring is a ferrule that cooperates with the shaft. The seat ring is a ferrule that cooperates with the bearing housing hole, and there is a gap between the shaft; the thrust ball bearing can only bear the axial load, and the one-way thrust load bearing can only bear Axial load in one direction, two-way thrust load bearing can withstand axial loads in two directions; thrust ball bearings can not limit the radial displacement of the shaft, the limit speed is very low, one-way thrust load bearing can limit one of the shaft and the housing Axial displacement of the direction, the two-way bearing can limit the axial displacement in both directions.

Thrust load bearing are used to support axial and radial combined loads with axial loads, but radial loads must not exceed 55% of axial loads. Compared with other thrust load bearing, this type of bearing has a low friction factor, high speed and self-aligning performance. The roller of the 29000 type bearing is an asymmetrical spherical roller, which can reduce the relative sliding of the roller and the raceway during operation, and has a long roller, a large diameter, a large number of rollers, a high load capacity, and is usually oil lubricated.

Individual low speed conditions can be lubricated with grease. In design selection, it should be preferred; 80000 thrust cylindrical roller bearings, 90000 thrust tapered roller bearings and AXK thrust needle bearings can withstand one-way axial loads, which is more axial than thrust ball bearings. The load capacity is much larger, and the rigidity is large and the axial space is small. Thrust cylindrical roller bearings and thrust needle roller bearings are suitable for low speed applications. Thrust tapered roller bearings have a slightly higher rotational speed than thrust cylindrical roller bearings.

Pay attention to the following points when installing thrust load bearing.

(1) Distinguish the tight ring and loose ring of the bearing (according to the inner diameter of the bearing, the hole diameter difference is O.1~O.5mm).

(2) Distinguish the stationary parts of the mechanism (ie, parts that do not move, mainly refers to the assembly).

(3) In any case, the loose ring of the thrust load bearing should always rest on the end face of the stationary part.

If you need the thrust load bearing or other bearings, please contact me any time!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.