Before disassembling the wheel hub, you should make preparations for the maintenance of the wheel hub, park the car steady and erect the axle to ensure the safety of maintenance work.

[1] Remove the decorative cover and dust cover from the hub shaft head.

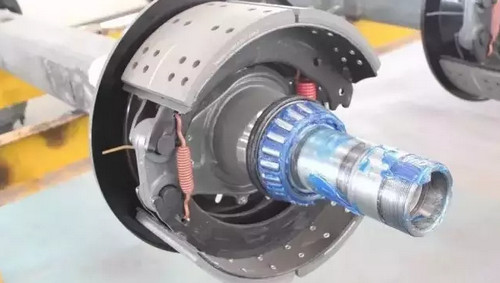

[2] Remove the tire nut and tire, taking care not to hurt the thread of the tire bolt. If it is a disc brake, remove the brake, and then remove the lock ring or pin with pliers.

[3] Remove the wheel hub with a special tool.

[4] Scrape off old grease from truck bearings, journal and hub cavity, clean the hub bearing and journal with a cleaning agent and dry with a cloth, and finally clean the hub cavity with a cloth.

[5] Check the truck bearings and bearing races, and find cracks, fatigue peeling, and loose bearing rollers. Replace the truck bearings. If pitting is found on the bearing race, the bearing should also be replaced.

[6] Check the fit between the inner diameter of the truck bearings and the journal. The fit clearance should not be greater than 0.10mm. When measuring the journal, it should be measured at the upper and lower parts of the vertical ground (the place where the largest wear is). If the fit clearance exceeds the specified use limit, the bearing should be replaced to restore the normal fit clearance. Burrs and pitting on the journal are not allowed to reduce the gap.

[7] After all parts meet the requirements, grease the inner bearing and put it into the hub.

[8] When applying grease to the inner cavity of truck bearings, be careful to squeeze the grease into the truck bearings until the grease comes out of the other side of the bearing. Apply a thin layer of grease to the hub cavity and shaft head cover to prevent rust. Be careful not to apply too much grease in the hub cavity, otherwise it will affect heat dissipation and braking.

[9] Put the hub and outer bearing back on the journal, screw the shaft head adjustment nut by hand, and then use the shaft head wrench to tighten the adjustment nut with the specified torque. After tightening the nut, you should turn the hub a few turns left and right to see the installation of the truck bearings; on the other hand, the bearings and the seat ring must be properly matched by rotation. At this time, the truck bearings tightness is appropriate, and the wheel can rotate freely without feeling the axial clearance.

[10] Finally, install parts such as the lock plate, fixing nut, tire, dust cover, and decorative cover.