First, the installation of the top wire locking ucp bearing:

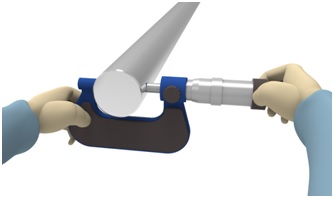

1.Check the accuracy of the shaft

Before installing the ucp bearing, check whether the dimensional tolerance of the shaft is qualified, whether the shaft is bent, bumped, burred, etc., and add some lubricant to the shaft appropriately.

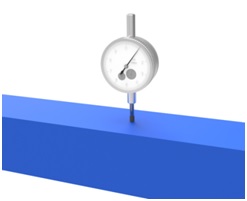

2. Check the rigidity and flatness of the mounting surface

The rigidity of the frame where the ucp bearing is installed must be sufficient, and the flatness of the installation site should not be greater than 0.15mm.

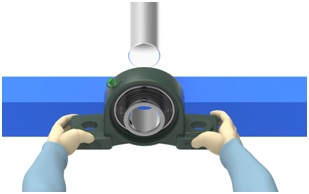

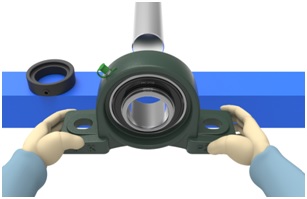

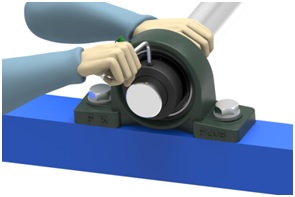

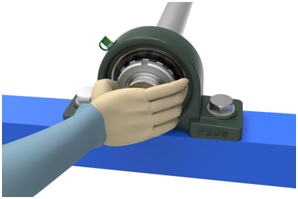

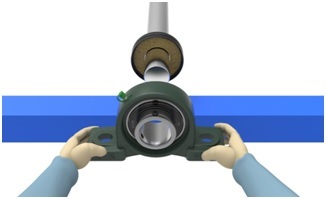

3.install ucp bearing

Avoid hitting ucp bearing with metal objects such as hammers for installation. Especially for ucp bearing with retaining ring seal, when the bearing is struck, it may cause the retaining ring to move inward, contact the inner sealing ring and cause friction during operation, causing the bearing to fail to rotate or the temperature to rise sharply and burn the ucp bearing. When the inner hole of the ucp bearing is tightly fitted with the shaft, it is recommended to use a pressure device to press the end face of the inner ring for installation.

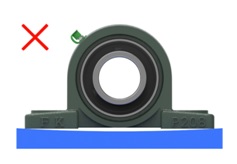

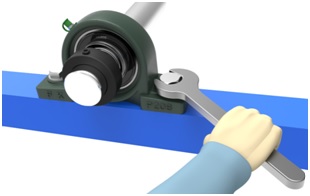

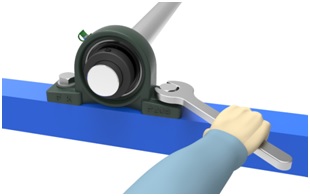

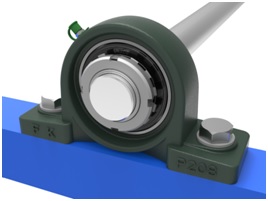

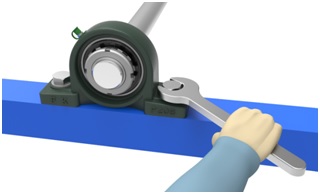

4. Pre-tightened bearing seat

Excessive torque of the lock bolt may cause deformation of the bearing seat, and the appropriate tightening torque is required to tighten the bolt. FK recommends that the lock bolt be used with the washer when installing the bearing seat, because if the lock bolt is used alone Hold the housing, the locking bolt may damage the housing.

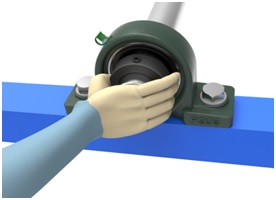

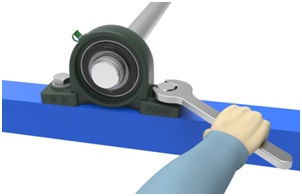

5. Tighten the bearing top wire

Tighten the top screw according to the recommended torque.

6. Retighten the bearing seat

Excessive torque of the locking bolt may cause deformation of the bearing seat.Use appropriate tightening torque to tighten the bolt.

Second, the installation of eccentric sleeve locking ucp bearing:

Note: The ucp bearing with eccentric sleeve is not recommended for situations where the direction of rotation will change, because the change in direction of rotation will cause the eccentric sleeve to loosen. The preparation for products with eccentric sleeves is the same as for products with top wires.

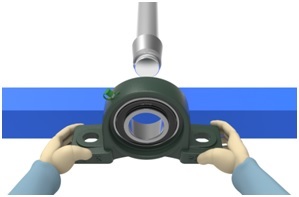

1.ucp bearing

Avoid hitting ucp bearing with metal objects such as hammers for installation. Especially for ucp bearing with retaining ring seal, when the bearing is struck, it may cause the retaining ring to move inward, contact the inner sealing ring and cause friction during operation, causing the bearing to rotate improperly or the temperature to rise and burn the bearing. . When the inner hole of the ucp bearing is tightly fitted with the shaft, it is recommended to use a pressure device to press the end face of the inner ring for installation.

2. Pre-tightened bearing seat

Excessive torque of the lock bolt may cause deformation of the bearing seat, and the appropriate tightening torque is required to tighten the bolt. FK recommends that the lock bolt be used with the washer when installing the bearing seat, because if the lock bolt is used alone Hold the housing, the locking bolt may damage the housing.

3.Eccentric sleeve

Assemble the eccentric sleeve on the inner ring boss, and manually rotate the eccentric sleeve in the direction of shaft rotation to temporarily tighten it.

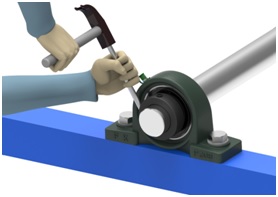

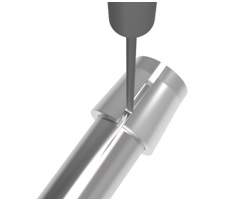

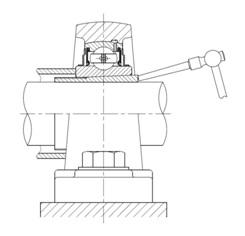

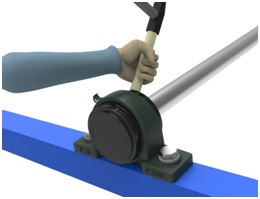

4. Turn the eccentric sleeve

Insert the tool rod into the cylindrical recessed hole of the outer diameter of the eccentric sleeve, and tap the tool rod to make the eccentric sleeve rotate in the shaft rotation direction, and hug the mounting shaft.

5.Lock the eccentric sleeve

Tighten the top wire on the eccentric sleeve to the shaft. See the FK product manual for recommended tightening torques.

6.Retighten the bearing seat

Excessive torque of the locking bolt may cause deformation of the bearing seat. Use appropriate tightening torque to tighten the bolt.

Third, the installation of locking sleeve locking ucp bearing:

Note: With adapter sleeve ucp bearing, even if it is subjected to shock load or vibration load, you don't need to worry about the shaft and inner ring being loose. However, the ucp bearing with adapter sleeve cannot be used in the case of bearing large axial loads. The preparation of ucp bearing with adapter sleeve is the same as the product with the cap wire.

1. Install the fixed bushing on the shaft

Adjust the position of the adapter sleeve so that the tapered part is in the middle of the bearing. To help install the adapter sleeve on the shaft, you can use a screwdriver or similar tool to pry the groove on the sleeve wide.

2.install ucp bearing

Place the tapered bore bearing on the adapter sleeve.

3.Pre-tensioned bearing seat

Excessive torque of the lock bolt may cause deformation of the bearing seat, and the appropriate tightening torque is required to tighten the bolt. FK recommends that the lock bolt be used with the washer when installing the bearing seat, because if the lock bolt is used alone Hold the housing, the locking bolt may damage the housing.

4. Install tight set bushing

Gently tap the bushing surface until the bearing and bushing are in proper contact.

5. Install bushing washer and nut

Insert the washer and tighten the nut manually

6.Lock bush nut

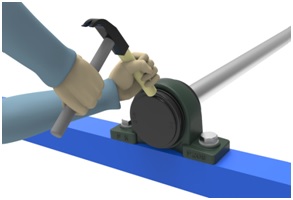

Use a tool (use a screwdriver without tools) to hit the groove of the nut with a hammer. Stop beating after the nut has turned 60-90 degrees.

Be careful not to knock on the retaining ring, and be careful not to over-tighten the nut, as this will cause deformation of the inner ring and cause heat to seize.

7. Nut lock

Bend the pull ring on the edge of the gasket and lock it against the slot of the nut to prevent the nut from loosening.

Be careful not to loosen the nut backwards to align the pull ring and the notch, but tighten the nut forward to align.

8.Retighten the bearing seat

Excessive torque of the locking bolt may cause deformation of the bearing seat. Use appropriate tightening torque to tighten the bolt.

Installation of ucp bearing with terminal cover:

The preparation, mounting of bearings on the shaft, and mounting of bearing housings are the same as for standard products.

1.Filling grease

In order to enhance the dustproof and waterproof effect, the rubber sealing lip inside the terminal cover and the internal space are filled with 2/3 space of grease.

2.install ucp bearing

Put a greased terminal cover on the shaft, and then install the ucp bearing (the method is the same as the standard product). It is recommended to chamfer the end of the shaft to avoid damaging the rubber sealing lip on the terminal cover.

3. Attach the terminal cover 1

Press the end cap that is threaded onto the shaft onto the bearing housing. Note that you cannot directly hit the surface of the terminal cover with a hammer. Use plastic or wood to hit the terminal cover at 45 degrees around the circumference of the terminal cover. You can't tap only one position.

4. Install the terminal cover 2

Note that you cannot directly hit the surface of the terminal cover with a hammer. Use plastic or wood to hit the terminal cover at 45 degrees around the circumference of the terminal cover. You can't tap only one position.